The Scott 4.5 SCBA is a high-performance‚ pressure-demand self-contained breathing apparatus designed for respiratory protection in hazardous environments. Lightweight and durable‚ it meets NFPA-1981 standards for reliability and safety‚ ensuring optimal performance in emergency situations. The manual provides comprehensive guidance on operation‚ maintenance‚ and safety protocols for users.

1.1 Overview of the Scott 4.5 SCBA

The Scott 4.5 SCBA is a pressure-demand self-contained breathing apparatus designed for use in hazardous environments. Certified by NIOSH and compliant with NFPA-1981 standards‚ it provides reliable respiratory protection. The system includes a high-pressure cylinder‚ pressure reducer‚ regulator‚ and facepiece. Lightweight and durable‚ it is ideal for firefighters and industrial workers. The manual ensures proper operation‚ maintenance‚ and safety protocols‚ making it a critical resource for trained operators.

1.2 Key Features of the Scott 4.5 SCBA

The Scott 4.5 SCBA features a high-pressure cylinder with a 4500 psig service pressure‚ ensuring extended operation in demanding environments. Its lightweight design enhances mobility‚ while the pressure-demand system provides a steady air supply. The facepiece and harness offer a secure‚ comfortable fit‚ and the control console with HUD displays vital information. NFPA-1981 compliance and NIOSH certification guarantee reliability and safety. These features make it a trusted choice for professionals requiring dependable respiratory protection.

1.3 Importance of the Manual for Users

The manual is essential for users of the Scott 4.5 SCBA‚ providing detailed instructions for safe operation‚ maintenance‚ and troubleshooting. It ensures compliance with safety standards and proper use‚ minimizing risks. The guide covers inspection procedures‚ cleaning‚ and parts replacement‚ crucial for maintaining the SCBA’s performance and longevity. Trained operators rely on this manual to ensure the equipment functions correctly‚ protecting users in hazardous environments. Adhering to the manual’s guidelines is vital for optimal safety and effectiveness.

Manual Overview

The manual provides comprehensive guidance for the Scott 4.5 SCBA‚ detailing its operation‚ maintenance‚ and safety protocols. It is an essential resource for users.

2.1 Purpose of the Scott 4.5 SCBA Manual

The Scott 4.5 SCBA manual serves as a detailed guide for users‚ outlining proper operation‚ maintenance‚ and safety measures. It ensures users understand the SCBA’s functionality.

2.2 Structure of the Manual

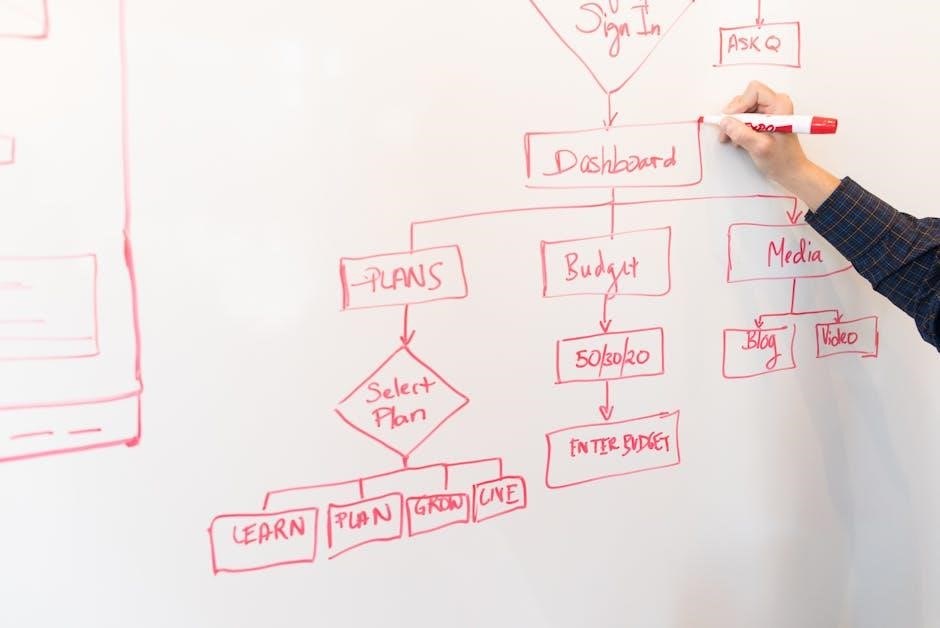

The Scott 4.5 SCBA manual is organized into logical sections to ensure easy navigation and understanding. It begins with an introduction‚ followed by detailed operating instructions‚ maintenance procedures‚ and safety precautions. Key sections include system components‚ troubleshooting‚ and regulatory compliance. The manual also covers technical specifications and accessories‚ providing a comprehensive guide for users. Each chapter is designed to address specific needs‚ from daily inspections to advanced maintenance‚ ensuring all aspects of the SCBA are thoroughly explained.

2.3 Key Sections of the Manual

The manual features essential sections‚ including operating instructions‚ maintenance schedules‚ and safety protocols. It provides detailed guidance on pre-operation checks‚ donning procedures‚ and emergency responses. Additional sections cover technical specifications‚ compliance with NFPA standards‚ and troubleshooting common issues. The manual also includes information on accessories‚ training requirements‚ and manufacturer guidelines‚ ensuring a complete understanding of the Scott 4.5 SCBA for optimal performance and safety.

System Components

The Scott 4;5 SCBA consists of a high-pressure cylinder‚ pressure reducer‚ regulator‚ facepiece‚ and harness. Additional components include the control console and HUD for monitoring breathing gas supply and system status.

3.1 High-Pressure Cylinder and Valve Assembly

The Scott 4.5 SCBA features a high-pressure cylinder with a rated service pressure of 4500 psig‚ ensuring extended operation in demanding environments. The valve assembly is designed for reliable gas flow control‚ with a quick-disconnect feature for easy cylinder replacement. The cylinder is constructed from durable materials to withstand harsh conditions and is certified for use in various respiratory protection scenarios‚ including firefighting and industrial applications.

3.2 Pressure Reducer and Regulator

The pressure reducer in the Scott 4.5 SCBA converts high-pressure gas from the cylinder to a usable pressure for breathing. The regulator ensures a consistent airflow‚ maintaining proper breathing gas supply. Designed for reliability‚ it features a Snap-Change mechanism for quick cylinder replacement. The regulator integrates with the control console‚ providing real-time pressure monitoring through the HUD display. This system ensures safe and efficient operation‚ critical for emergency response scenarios.

3.3 Facepiece and Harness

The facepiece and harness of the Scott 4.5 SCBA are designed for comfort and durability. The facepiece provides a secure seal‚ while the harness features adjustable straps and a lumbar pad for optimal weight distribution. The quick-release mechanism allows for easy removal in emergency situations. The facepiece is constructed from durable rubber‚ ensuring a tight seal and long-lasting performance. The harness includes a quick disconnect for the breathing hose‚ enhancing versatility and ease of use during operations.

3.4 Control Console and HUD

The control console and HUD (Heads-Up Display) are central to the Scott 4.5 SCBA’s operation. The control console houses the pressure reducer and regulator‚ ensuring consistent airflow. The HUD provides real-time data‚ including air supply levels‚ pressure‚ and system status‚ allowing users to monitor their environment and breathing apparatus efficiently. The HUD’s clear display enhances situational awareness‚ while the console’s intuitive design simplifies system control‚ making it a critical component for safe and effective operation in hazardous conditions.

Operating Instructions

The Scott 4.5 SCBA manual outlines essential steps for safe operation‚ including pre-operation checks‚ donning‚ breathing gas management‚ and emergency procedures to ensure user safety and system reliability.

4.1 Pre-Operation Checks

Pre-operation checks ensure the Scott 4.5 SCBA functions properly. Inspect the high-pressure cylinder for damage and verify its pressure meets requirements. Check the regulator‚ pressure reducer‚ and facepiece for proper connection and function. Ensure the control console and HUD display accurate readings. Test the breathing gas flow and verify the alarm systems are operational. Examine the harness and straps for wear or damage. Always follow the manual’s detailed checklist to guarantee safety and compliance with operational standards.

4.2 Donning and Doffing the SCBA

Donning the Scott 4.5 SCBA begins with inspecting the equipment for damage. Place the harness on your shoulders‚ ensuring proper fit and adjustment. Connect the facepiece securely‚ checking for a tight seal. Attach the control console and ensure the HUD displays correctly. Verify cylinder pressure and breathing gas flow. Doffing involves disconnecting the facepiece‚ removing the harness‚ and storing the SCBA according to guidelines. Always follow the manual’s step-by-step instructions to ensure safety and proper equipment handling.

4.3 Breathing Gas Supply and Flow

The Scott 4.5 SCBA delivers a consistent breathing gas supply through its pressure-demand system‚ ensuring a safe airflow rate. The regulator maintains a positive pressure inside the facepiece‚ preventing contaminants from entering. Users can monitor cylinder pressure via the control console‚ which alerts when levels drop below safe thresholds. The system automatically adjusts gas flow based on breathing rate‚ providing reliable respiratory protection. Always ensure the cylinder is fully charged and the regulator is functioning correctly before use to maintain optimal performance and safety.

4.4 Emergency Procedures

In emergency situations‚ the Scott 4.5 SCBA is designed to provide reliable breathing gas supply. Users should monitor low-air warnings and alarms. If the system fails‚ activate the emergency bypass to ensure continuous airflow. Stay calm‚ assess the situation‚ and follow evacuation procedures. Conduct a buddy check if possible‚ and ensure all connections are secure. Always follow established emergency protocols and refer to the manual for specific instructions to maintain safety and functionality in critical conditions. Proper training is essential for effective response.

Maintenance and Inspection

Regular maintenance ensures optimal performance and safety. Daily inspections include checking cylinders‚ regulators‚ and harnesses for damage or wear. Cleaning and disinfecting follow strict protocols to prevent contamination. Annual maintenance requires certified technician inspections to meet NFPA standards and ensure compliance. Proper upkeep extends equipment lifespan and guarantees reliability in critical situations. Always refer to the manual for detailed procedures and guidelines. Adherence to maintenance schedules is crucial for user safety and system functionality. Promptly address any issues to avoid downtime and ensure readiness for emergency responses. Regular servicing also helps identify and replace wearable parts before they fail‚ preventing unexpected malfunctions during operations. By following a structured maintenance routine‚ users can maintain the SCBA’s integrity and performance over time. This proactive approach minimizes risks and ensures the equipment remains in optimal condition for its intended use. Documentation of all maintenance activities is recommended for record-keeping and compliance purposes. Understanding the importance of each step ensures the SCBA operates effectively when needed most. Consistent and thorough maintenance is vital for the longevity and reliability of the Scott 4;5 SCBA. Users must stay vigilant and proactive in their maintenance practices to uphold safety standards and equipment performance. Regular training on maintenance procedures further enhances the ability to identify and resolve potential issues efficiently. A well-maintained SCBA is essential for protecting users in hazardous environments‚ making maintenance a top priority. Always follow the manufacturer’s guidelines to ensure all procedures are performed correctly and safely. Proper maintenance not only extends the life of the SCBA but also ensures it functions as intended during emergencies. By prioritizing maintenance‚ users can trust their equipment to perform reliably in critical situations. Regular inspections and timely repairs are key to maintaining the SCBA’s operational readiness and user confidence. Adhering to established maintenance protocols ensures the Scott 4.5 SCBA remains a dependable tool for respiratory protection in demanding environments. Consistent upkeep also helps prevent costly repairs and reduces the risk of unexpected failures. A comprehensive maintenance routine supports the overall performance and safety of the SCBA‚ making it an indispensable part of user preparedness. By staying committed to regular maintenance‚ users can ensure their Scott 4.5 SCBA is always ready for action. Proper care and attention to detail during inspections and servicing are critical for maintaining the integrity of the equipment. Users should never overlook the importance of following the manual’s maintenance instructions to ensure optimal functionality and safety. Regular maintenance is an investment in the reliability and longevity of the Scott 4.5 SCBA‚ providing users with peace of mind during operations. By incorporating maintenance into routine practices‚ users can uphold the highest standards of safety and equipment performance. Consistent and thorough maintenance ensures the Scott 4.5 SCBA continues to meet the demands of its intended use effectively. Always prioritize maintenance to safeguard both the equipment and the user in high-stakes environments. Regular maintenance is essential for ensuring the Scott 4.5 SCBA operates at peak performance levels‚ providing reliable protection when it matters most. By adhering to maintenance schedules and guidelines‚ users can trust their SCBA to perform flawlessly in emergency situations. Proper maintenance practices are fundamental to the safe and effective operation of the Scott 4.5 SCBA‚ ensuring it remains a vital tool for respiratory protection. Users must remain dedicated to regular maintenance to uphold the equipment’s performance and reliability. A well-maintained SCBA is crucial for user safety and operational success in hazardous environments. Regular maintenance ensures the Scott 4.5 SCBA continues to serve as a dependable and trustworthy piece of equipment. By prioritizing maintenance‚ users can ensure their SCBA is always prepared to provide essential respiratory protection in critical moments. Consistent upkeep and adherence to maintenance protocols are vital for the longevity and effectiveness of the Scott 4.5 SCBA. Users should never underestimate the importance of regular maintenance in ensuring the equipment’s optimal performance and safety. Proper maintenance practices are essential for extending the life of the SCBA and maintaining its reliability in demanding situations. By following the manufacturer’s maintenance guidelines‚ users can ensure their Scott 4.5 SCBA remains in excellent working condition. Regular maintenance is a critical component of SCBA ownership‚ ensuring it continues to provide reliable protection for users in hazardous environments. Consistent and thorough maintenance routines are key to upholding the performance and safety of the Scott 4.5 SCBA. Users must stay proactive in their maintenance efforts to ensure the equipment remains operational and ready for use. Proper maintenance not only ensures the SCBA’s functionality but also enhances user confidence in its reliability during emergencies. By incorporating regular maintenance into routine practices‚ users can maintain the Scott 4.5 SCBA’s peak performance and extend its service life. Regular inspections and timely maintenance are essential for identifying and addressing potential issues before they impact the SCBA’s performance. Users should always follow the manual’s maintenance instructions to ensure the equipment remains in optimal condition. Proper maintenance is crucial for ensuring the Scott 4.5 SCBA continues to meet the rigorous demands of its intended use. By prioritizing maintenance‚ users can trust their SCBA to deliver reliable protection in high-stakes environments. Regular maintenance ensures the Scott 4.5 SCBA remains a vital and dependable tool for respiratory protection in emergency situations. Users must remain committed to regular upkeep to ensure the equipment’s safety and functionality. Proper maintenance practices are essential for maintaining the integrity and performance of the Scott 4.5 SCBA. By adhering to maintenance schedules‚ users can ensure their SCBA is always ready to provide essential protection. Regular maintenance is a critical aspect of SCBA ownership‚ ensuring it continues to operate effectively and safely in hazardous environments. Users should never overlook the importance of following the manual’s maintenance guidelines to ensure optimal performance. Consistent and thorough maintenance is vital for upholding the reliability and longevity of the Scott 4.5 SCBA. By staying proactive with maintenance‚ users can ensure their equipment remains in excellent working condition and ready for action. Proper maintenance not only extends the life of the SCBA but also ensures it functions flawlessly when needed most. Regular inspections and timely repairs are key to maintaining the Scott 4.5 SCBA’s operational readiness and user confidence. Users must prioritize maintenance to ensure the equipment remains safe and reliable in critical situations. By following the manufacturer’s maintenance instructions‚ users can trust their SCBA to deliver optimal performance and protection. Regular maintenance is essential for ensuring the Scott 4.5 SCBA continues to meet the highest standards of safety and functionality. Users should always incorporate maintenance into their routine to uphold the equipment’s integrity and performance. Proper upkeep ensures the SCBA remains a dependable tool for respiratory protection in demanding environments. By adhering to maintenance protocols‚ users can extend the life of their Scott 4.5 SCBA and ensure it remains operational for years to come. Regular maintenance is a critical investment in the safety and reliability of the Scott 4.5 SCBA. Users must stay committed to regular inspections and servicing to ensure the equipment’s peak performance. Proper maintenance practices are fundamental to the safe and effective operation of the SCBA‚ providing users with confidence in its reliability. By prioritizing maintenance‚ users can ensure their Scott 4.5 SCBA remains a vital and trustworthy piece of equipment in emergency situations. Regular maintenance ensures the SCBA continues to function optimally‚ providing essential respiratory protection in hazardous environments. Users should never underestimate the importance of following the manual’s maintenance guidelines to ensure the equipment’s longevity and performance. Proper maintenance is crucial for upholding the integrity and functionality of the Scott 4.5 SCBA‚ ensuring it remains ready for action when needed. By incorporating regular maintenance into routine practices‚ users can trust their SCBA to deliver reliable protection in critical moments. Consistent upkeep and adherence to maintenance protocols are essential for the Scott 4.5 SCBA’s optimal performance and user safety. Users must remain proactive in their maintenance efforts to ensure the equipment remains operational and reliable. Proper maintenance practices are vital for extending the life of the SCBA and ensuring it continues to meet the demands of its intended use. By following the manufacturer’s guidelines‚ users can maintain the Scott 4.5 SCBA’s performance and safety standards. Regular maintenance is a key component of SCBA ownership‚ ensuring it remains a dependable tool for respiratory protection in emergency situations. Users should always prioritize maintenance to ensure the equipment’s functionality and readiness for use. Proper upkeep ensures the Scott 4.5 SCBA continues to provide reliable protection in high-stakes environments‚ making regular maintenance a top priority for users. By staying committed to maintenance‚ users can ensure their SCBA remains in excellent working condition and ready to perform when needed. Regular inspections and timely servicing are essential for maintaining the Scott 4.5 SCBA’s operational readiness and user confidence. Users must adhere to maintenance schedules to ensure the equipment’s safety and reliability in critical situations. Proper maintenance practices are essential for upholding the performance and longevity of the Scott 4.

5.1 Daily Inspection Checklist

The daily inspection ensures the Scott 4.5 SCBA is ready for use. Check the high-pressure cylinder for damage or wear‚ ensuring the valve is fully open and functioning correctly. Inspect the regulator‚ pressure reducer‚ and hoses for any signs of damage or leaks. Examine the facepiece‚ harness‚ and straps for proper fit and integrity. Verify that all connections are secure and that the control console and HUD display are functioning properly. Refer to the manual for detailed inspection steps and documentation of findings. Address any issues promptly to ensure safety and reliability.

5.2 Cleaning and Disinfecting Procedures

Cleaning and disinfecting the Scott 4.5 SCBA are critical for maintaining hygiene and functionality. Use a soft‚ non-abrasive cloth and mild soap solution to wipe down exterior surfaces. Avoid harsh chemicals or abrasive materials that may damage components. Disinfect high-touch areas like the facepiece and harness using a 70% isopropyl alcohol solution. Ensure all parts are dry before storage to prevent moisture-related issues. Follow the manual’s specific guidelines for cleaning sensitive components to maintain performance and safety.

5.3 Replacement of Wearable Parts

Regular inspection and replacement of wearable parts‚ such as the facepiece‚ harness‚ and O-rings‚ are essential to ensure the Scott 4.5 SCBA’s optimal performance and safety. Replace any worn or damaged components immediately‚ using only Scott-approved parts. Follow the manual’s detailed instructions for part removal and installation to maintain the integrity of the system. Proper replacement ensures reliable operation‚ preventing leaks or failures during critical situations. Always refer to the manual for specific guidelines and timelines for part replacement.

5.4 Annual Maintenance Requirements

The Scott 4.5 SCBA requires annual maintenance to ensure compliance with safety standards and optimal performance. This includes a thorough inspection of all components‚ hydrostatic testing of cylinders every five years‚ and replacement of perishable parts. Maintenance must be performed by certified personnel following the manual’s guidelines. Annual servicing ensures the SCBA remains reliable and safe for use‚ adhering to NIOSH certification requirements and NFPA standards. Always refer to the manual for detailed procedures and timelines for annual maintenance tasks.

Safety Precautions

Adhere to cautions and limitations of use to ensure safe operation. Always operate within NIOSH certification guidelines and follow proper procedures to minimize risks in hazardous environments.

6.1 Cautions and Limitations of Use

Use the Scott 4.5 SCBA only with approved components and within NIOSH certification guidelines. Avoid exposure to extreme temperatures or chemicals that may degrade materials. Ensure proper training before use to prevent misuse. Regular inspections are crucial to maintain functionality. Never alter or modify the SCBA beyond manufacturer specifications. Operate only in environments compatible with the device’s design to ensure safety and effectiveness. Always follow pre-operation checks to identify potential issues before deployment.

6.2 Operating Temperature and Environment

The Scott 4.5 SCBA is designed to operate in temperatures ranging from -20°F to 125°F (-29°C to 52°C). It is suitable for use in various environments‚ including hazardous industrial settings and emergency response scenarios. However‚ extreme conditions beyond these limits may affect performance. Ensure the SCBA is not exposed to direct flames or corrosive substances. Always maintain the device in accordance with NIOSH certification guidelines to ensure reliability and safety in diverse operating conditions.

6.3 Storage and Transportation Guidelines

The Scott 4.5 SCBA should be stored in a clean‚ dry environment‚ away from direct sunlight and extreme temperatures. Avoid exposure to chemicals or corrosive substances. When transporting‚ use a protective carrying case to prevent damage. Ensure the cylinder is securely fastened and the regulator is protected. Follow NIOSH guidelines for handling and storage to maintain the SCBA’s integrity and performance. Proper storage and transportation are critical for ensuring the device remains operational and ready for use in emergency situations.

Technical Specifications

The Scott 4.5 SCBA features a high-pressure cylinder with a 4500 psig rating‚ providing extended air supply duration. Designed to meet NFPA-1981 standards‚ it ensures reliability and performance in demanding environments‚ making it a critical tool for fire and rescue operations.

7.1 Service Pressure and Cylinder Capacity

The Scott 4.5 SCBA operates at a maximum service pressure of 4500 psig‚ ensuring reliable performance in high-stress environments. The cylinder capacity is designed to provide an extended air supply‚ meeting NFPA-1981 standards for firefighter respiratory protection. Constructed with durable materials‚ the cylinder and valve assembly are built to withstand harsh conditions‚ delivering consistent airflow and pressure regulation. This design ensures optimal breathing support during prolonged operations‚ critical for user safety and operational effectiveness.

7.2 Weight and Dimensions

The Scott 4.5 SCBA is designed to be lightweight and compact‚ reducing user fatigue during extended operations. Its dimensions are optimized for mobility‚ allowing easy maneuverability in tight spaces. The SCBA’s weight distribution ensures comfort and balance‚ while its size meets NFPA standards for first responder equipment. Constructed with durable materials‚ the Scott 4.5 SCBA provides reliable performance without compromising on portability or ease of use‚ making it a practical choice for firefighters and emergency responders.

7.3 Compliance with NFPA Standards

The Scott 4.5 SCBA is fully compliant with NFPA-1981 (2013 Edition) standards for self-contained breathing apparatuses. This certification ensures the SCBA meets rigorous performance‚ safety‚ and durability requirements for firefighting and emergency response applications. Compliance confirms the device’s reliability in hostile environments‚ providing users with confidence in its ability to deliver consistent respiratory protection under extreme conditions while adhering to industry guidelines.

Troubleshooting

The Scott 4.5 SCBA manual includes error codes‚ low-air alarms‚ and common issues like pressure failures. It provides solutions and reset procedures for optimal performance.

8.1 Common Issues and Solutions

The Scott 4.5 SCBA manual addresses common issues such as low-air alarms‚ regulator malfunctions‚ and pressure failures. Solutions include checking cylinder pressure‚ inspecting hoses for damage‚ and ensuring proper regulator function. Users are advised to refer to the troubleshooting guide for step-by-step fixes and to reset alarms only after resolving underlying issues. Regular maintenance and inspections can prevent many of these problems‚ ensuring reliable operation in critical situations.

8.2 Error Indications and Alarms

The Scott 4.5 SCBA features error indications and alarms to alert users of system malfunctions. Low-air warnings‚ regulator issues‚ or pressure drops trigger audible and visual alerts. The control console displays error codes‚ such as E1 or E2‚ guiding users to specific solutions. Proper alarm reset procedures must be followed to ensure system functionality. Refer to the manual for detailed explanations of error codes and corrective actions to maintain safety and operational integrity.

8.3 Resetting the System

Resetting the Scott 4.5 SCBA involves powering off and on to clear error codes. After addressing the issue‚ turn the system off‚ wait 30 seconds‚ and restart. Ensure the HUD displays normal operation and all alarms are silenced. If the low-air alarm sounds‚ manually reset it by pressing the reset button. Always refer to the manual for detailed reset procedures to ensure proper functionality and safety. Failure to reset correctly may result in system malfunctions during operation.

Regulatory Compliance

The Scott 4.5 SCBA is NIOSH certified and complies with NFPA-1981 (2013 Edition) standards‚ ensuring it meets rigorous safety requirements for respiratory protection in hazardous environments.

9.1 NIOSH Certification

The Scott 4.5 SCBA is certified by NIOSH under approval number TC-13F-80‚ ensuring compliance with federal respiratory protection standards; This certification confirms the SCBA meets strict safety‚ performance‚ and reliability criteria for use in hazardous environments. NIOSH certification involves rigorous testing of the SCBA’s ability to provide a secure air supply‚ maintain proper fit‚ and function under extreme conditions. Users can trust the Scott 4.5 SCBA to deliver reliable respiratory protection in emergency situations‚ as verified by NIOSH’s comprehensive evaluation process.

9.2 NFPA-1981 Standards

The Scott 4.5 SCBA is fully compliant with NFPA-1981 (2013 Edition) standards for self-contained breathing apparatuses. These standards ensure the SCBA meets rigorous design‚ performance‚ and safety requirements for use in firefighting and emergency response. Compliance includes durability‚ reliability‚ and compatibility with other firefighting equipment. The SCBA undergoes thorough testing to ensure it provides consistent airflow‚ clear communication‚ and secure fit under extreme conditions‚ making it a trusted choice for first responders and industrial users.

9.4 Compliance with Local Regulations

The Scott 4.5 SCBA must comply with local regulations and workplace safety standards. Users should verify that the SCBA meets all applicable local laws and fire department requirements. While the SCBA is designed to meet or exceed national standards like NFPA-1981‚ local regulations may vary. It is the responsibility of the user or organization to ensure compliance‚ potentially requiring additional documentation or certifications. Always consult local authorities to confirm adherence to specific regional requirements before deployment.

Accessories and Optional Equipment

The Scott 4.5 SCBA supports a range of approved accessories‚ including communication devices‚ customizable harnesses‚ and optional breathing gas connectors. These enhance functionality and user comfort.

10.1 Approved Accessories

The Scott 4.5 SCBA offers a variety of approved accessories to enhance functionality. These include communication systems‚ customizable harnesses‚ and breathing gas connectors. All accessories are designed to meet NIOSH standards‚ ensuring compatibility and safety. Users can choose from optional features like integrated voice amplifiers and extended-duration cylinders. These additions improve comfort and performance in demanding environments. Properly approved accessories are essential for maintaining compliance and optimizing the SCBA’s performance in various operational scenarios.

10.2 Optional Features and Upgrades

The Scott 4.5 SCBA offers optional features to customize performance. Upgrades include advanced communication systems‚ enhanced HUD displays‚ and extended-duration cylinders. Users can opt for integrated thermal imaging or improved harness ergonomics. Additional upgrades may involve advanced monitoring systems for real-time data tracking. These optional features enhance versatility‚ ensuring the SCBA meets specific user needs while maintaining compliance with safety standards. Upgrades are designed to integrate seamlessly with existing components‚ preserving the SCBA’s reliability and ease of use in critical situations.

Training and User Qualifications

Users must complete certified training programs to operate the Scott 4.5 SCBA effectively. Training covers SCBA functionality‚ safety protocols‚ and emergency procedures‚ ensuring operator proficiency and compliance with standards.

11.1 Training Requirements

Training is essential for safe and effective use of the Scott 4.5 SCBA. Users must complete a certified program covering SCBA functionality‚ safety protocols‚ and emergency procedures. Training ensures operators understand proper donning‚ breathing gas management‚ and system maintenance. Certification must be renewed periodically to stay compliant with NIOSH and NFPA standards. Practical exercises and theoretical knowledge are combined to prepare users for real-world scenarios.

Manufacturer Guidelines

11.2 Operator Certification

Operator certification ensures users are proficient with the Scott 4.5 SCBA. Certification requires completing a training program and passing a competency assessment. Operators must demonstrate understanding of SCBA operation‚ safety protocols‚ and emergency procedures. Certification is valid for a specified period‚ after which recertification is mandatory. Proper documentation and compliance with NFPA standards are required to maintain certification. Certified operators are authorized to use the SCBA in operational settings‚ ensuring safe and effective performance.