Exploring connections between art and humanities, the 11th edition delves into cultural influences, offering a comprehensive study of artistic expression.

Digital access is sought via platforms like Studocu and VitalSource, though caution regarding unauthorized downloads is advised for ethical reasons.

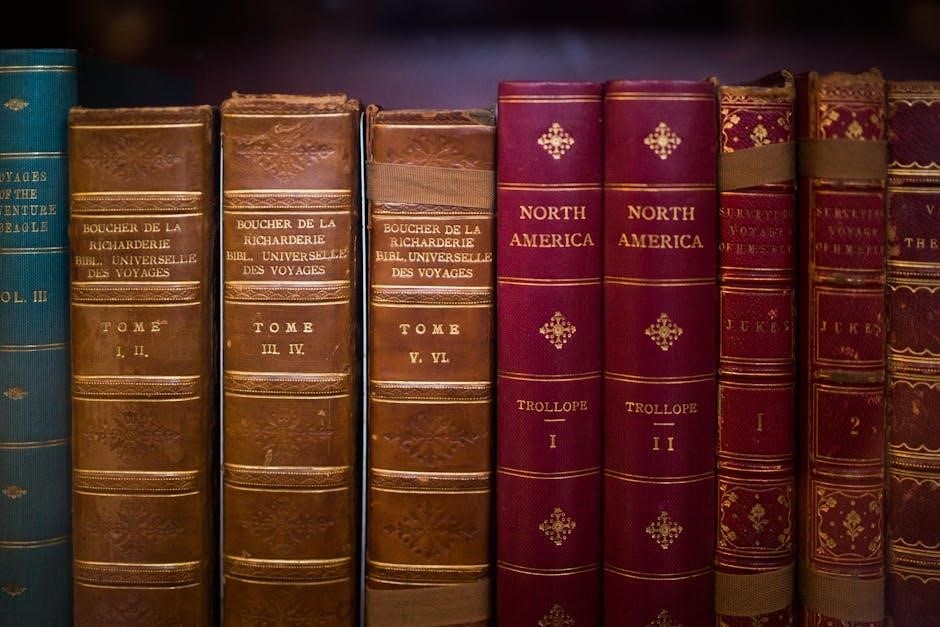

Overview of the Textbook

“Humanities Through the Arts” 11th Edition presents a broad exploration of artistic disciplines – visual, performing, and literary – within their historical and cultural contexts. The textbook emphasizes the interconnectedness of these forms and their reflection of societal values.

Students seek the PDF version for convenient access, often exploring platforms like Studyplight and SMART Academy. However, it’s crucial to prioritize legitimate sources like VitalSource to ensure copyright compliance and avoid potential risks associated with unauthorized downloads.

The text features interactive elements and detailed discussions, fostering a deeper understanding of artistic problems and contemporary values.

Significance of the 11th Edition

The 11th edition of “Humanities Through the Arts” maintains its relevance by incorporating contemporary artworks and revising discussions of core concepts. Its significance lies in providing a current and comprehensive overview of the humanities, appealing to students seeking accessible learning materials.

The demand for a PDF version highlights the need for digital resources, yet ethical considerations regarding copyright and legitimate access remain paramount. Platforms offering downloads require careful evaluation.

This edition’s focus on interactive elements and detailed analyses ensures continued academic value for students and educators alike.

Authors: Lee Jacobus & F. David Martin

Lee Jacobus and F. David Martin’s collaborative work establishes “Humanities Through the Arts” as a cornerstone text. Their combined expertise ensures a thorough exploration of artistic and cultural connections, fostering a deeper understanding of the humanities.

The authors’ dedication to detailed discussions and problem-solving within the arts is evident throughout the 11th edition. This commitment enhances the textbook’s academic rigor and practical application.

The continued availability of the text, including digital formats, reflects their lasting impact on humanities education.

Core Concepts Explored in the Textbook

The textbook defines humanities, exploring art’s interrelation with history and culture. It analyzes style, symbolism, societal roles, and cultural values effectively.

Defining the Humanities

The humanities encompass disciplines like history, philosophy, religion, languages, and literature, fostering critical thinking and cultural understanding. “Humanities Through the Arts” explores these fields through artistic expression, examining how art reflects and shapes human values.

This edition emphasizes the study of fine and performing arts, alongside media and cultural studies, providing a broad perspective. Accessing the PDF often involves platforms like VitalSource, offering digital textbook options, though ethical considerations regarding copyright remain crucial.

The Interrelation of Arts and Humanities

“Humanities Through the Arts” demonstrates how artistic creations are deeply intertwined with historical, philosophical, and cultural contexts. The 11th edition highlights this connection, showcasing how art both reflects and influences societal values and beliefs.

Exploring painting, sculpture, music, and literature, the textbook reveals their shared themes and mutual impact. Digital access to the PDF, via platforms like Studocu, facilitates study, but respecting intellectual property is paramount.

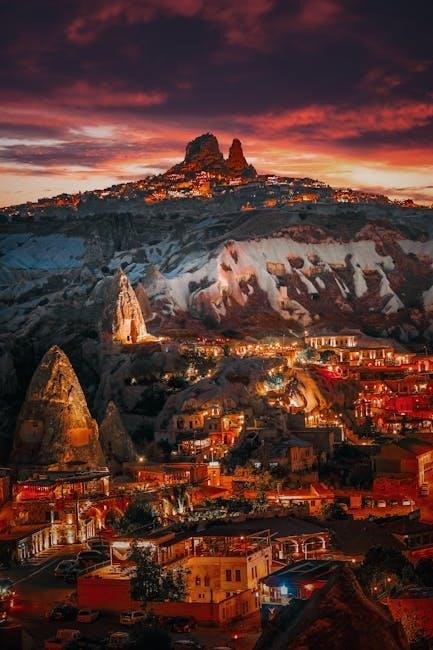

Cultural and Historical Context of Art

“Humanities Through the Arts” 11th edition emphasizes that art doesn’t exist in a vacuum; it’s a product of its time and place. The textbook meticulously examines how historical events, philosophical ideas, and cultural norms shape artistic expression.

From ancient sculptures to contemporary films, each artwork is analyzed within its specific context. Seeking a PDF version through platforms like VitalSource offers convenient access, but ethical considerations regarding copyright must be observed.

Art Forms Covered in the Textbook

The textbook comprehensively covers visual, performing, and literary arts, including painting, music, poetry, and film.

PDF access via platforms like Amazon provides a digital format for studying these diverse artistic expressions.

Visual Arts: Painting, Sculpture, and Architecture

This section meticulously examines painting, sculpture, and architecture, analyzing stylistic evolution and technical mastery throughout history. The 11th edition’s PDF version facilitates detailed study of iconic artworks and architectural marvels, fostering a deeper understanding of their cultural contexts.

Interactive elements within the text encourage critical analysis of artistic problems, while discussions explore contemporary values reflected in these visual forms. Accessing the PDF allows students to engage with high-quality images and in-depth analyses, enhancing their appreciation for visual artistry.

Performing Arts: Music, Dance, and Theatre

The textbook’s exploration of music, dance, and theatre reveals their profound impact on society and cultural expression. The 11th edition PDF provides a rich resource for understanding the historical development and artistic techniques within these disciplines.

Detailed discussions analyze performance styles, musical compositions, and dramatic structures, fostering critical thinking. Interactive elements encourage students to explore the interplay between performer, audience, and artistic intent, enhancing their appreciation for the performing arts.

Literary Arts: Poetry, Prose, and Drama

“Humanities Through the Arts” 11th edition PDF offers a comprehensive study of literary forms – poetry, prose, and drama – and their cultural significance. The text examines diverse genres, authors, and historical contexts, fostering a deeper understanding of narrative structure and stylistic techniques.

Detailed analyses explore symbolism, themes, and the relationship between literature and society. Interactive elements encourage critical interpretation and appreciation for the power of language, enriching the student’s literary experience.

Film as an Art Form

“Humanities Through the Arts” 11th edition PDF recognizes film as a significant modern art form, analyzing its aesthetic, narrative, and cultural impact. The textbook explores cinematic techniques – cinematography, editing, and sound design – and their contribution to storytelling.

Discussions delve into film’s reflection of societal values, historical events, and philosophical ideas. Contemporary examples illustrate film’s evolving role, fostering critical thinking about its artistic merit and influence.

Key Themes and Approaches

The 11th edition emphasizes analyzing artistic style, symbolism, and the societal role of art, fostering a deeper understanding of cultural values.

Interactive elements promote critical engagement with artistic problems and contemporary values.

Analyzing Artistic Style and Technique

This textbook meticulously examines how artistic styles evolve and are executed, providing detailed discussions of technique across diverse art forms. It encourages students to critically assess the choices artists make, considering the historical and cultural context influencing their work.

The 11th edition’s interactive elements facilitate a close study of artistic problems, prompting students to analyze composition, color palettes, and form. Understanding these elements unlocks deeper insights into the artist’s intent and the artwork’s overall meaning, enhancing appreciation.

Understanding Symbolism and Meaning in Art

The 11th edition emphasizes deciphering the layers of symbolism embedded within artworks, moving beyond surface-level observation. It equips students with the tools to interpret artistic intent and uncover hidden meanings, recognizing that art often communicates complex ideas through symbolic representation.

Exploring cultural values and historical context is crucial; the textbook highlights how symbols shift and evolve across time and societies. This approach fosters a nuanced understanding of art’s role in reflecting and shaping human beliefs and experiences.

The Role of Art in Society

“Humanities Through the Arts” 11th edition investigates art’s profound impact on societal structures and cultural values. It examines how artistic expression both reflects and influences social norms, political ideologies, and collective identities throughout history.

The textbook explores art as a catalyst for change, a means of social commentary, and a powerful tool for preserving cultural heritage. It emphasizes the dynamic interplay between art, artists, and the communities they inhabit, fostering critical thinking about art’s agency.

Art and Cultural Values

“Humanities Through the Arts” 11th edition meticulously analyzes the intricate relationship between artistic creations and the cultural values they embody. It demonstrates how art serves as a repository of a society’s beliefs, traditions, and ethical frameworks, offering insights into its worldview.

The text explores how cultural contexts shape artistic styles and themes, and conversely, how art can challenge, reinforce, or transform prevailing cultural norms. It highlights the importance of understanding art within its historical and societal milieu.

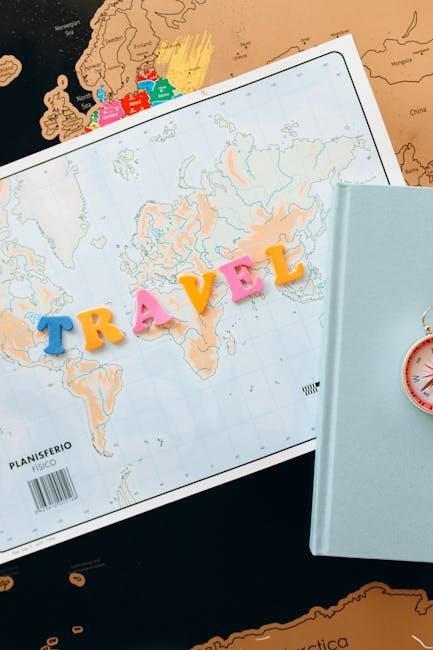

Accessing the 11th Edition PDF

Legitimate sources include VitalSource, while platforms like Studocu offer access, but caution is advised regarding potential risks of unauthorized downloads.

Legitimate Sources for PDF Download

Obtaining the “Humanities Through the Arts” 11th Edition PDF legally ensures access to a quality resource and respects copyright laws. VitalSource is a reliable platform offering digital textbooks, including this edition, with ISBN 9781264360215.

McGraw-Hill, the publisher, may also offer direct purchase options. While sites like Studocu may host copies, verifying their legitimacy is crucial to avoid potential legal and security risks associated with unauthorized downloads. Prioritizing official channels guarantees a complete and accurate version of the textbook.

Potential Risks of Unauthorized Downloads

Seeking a “Humanities Through the Arts” 11th Edition PDF from unofficial sources carries significant risks. These downloads often contain malware, viruses, or compromised software, endangering your device and personal information.

Furthermore, accessing copyrighted material illegally constitutes a violation of intellectual property rights, potentially leading to legal consequences. Unverified PDFs may also be incomplete, contain errors, or lack crucial interactive elements present in the legitimate version, hindering your learning experience. Always prioritize legal and secure access.

Studocu and Similar Platforms

Platforms like Studocu often host user-uploaded content, including potential PDFs of “Humanities Through the Arts” 11th Edition. However, the legality and quality of these uploads are questionable. While seemingly offering free access, these sources frequently violate copyright regulations.

Content may be outdated, incomplete, or contain inaccuracies. Relying on such platforms poses risks, and legitimate sources – like VitalSource or the publisher – are strongly recommended for a reliable and ethical learning experience.

VitalSource Digital Textbook Options

VitalSource provides a legitimate avenue for accessing the “Humanities Through the Arts” 11th Edition in digital format. Offering both rental and purchase options, it ensures legal and reliable access to the complete textbook content.

The Digital ISBN for this edition is 9781264360215. VitalSource’s platform often includes interactive features, enhancing the learning experience. Avoiding unauthorized PDF downloads protects intellectual property and supports the authors and publisher.

ISBN and Publication Details

Key identifiers include Print ISBN: 9781264069620 and Digital ISBN: 9781264360215, published by McGraw-Hill Higher Education.

These numbers are crucial for locating the correct edition when seeking legitimate digital or print copies.

Print ISBN: 9781264069620

This ISBN specifically identifies the physical, printed version of “Humanities Through the Arts,” 11th Edition. Utilizing this number ensures you’re referencing the correct textbook edition for coursework or study.

While a free PDF version is often sought, obtaining the book through authorized channels, using this ISBN, supports the authors and publisher. Be wary of unofficial sources offering downloads, as they may contain inaccuracies or violate copyright laws.

Legitimate copies, identified by this ISBN, provide reliable content for academic purposes.

Digital ISBN: 9781264360215

This ISBN uniquely identifies the digital edition of “Humanities Through the Arts,” 11th Edition, often accessed through platforms like VitalSource. It’s crucial when searching for the eTextbook to ensure you’re acquiring the correct version for your studies.

The demand for a free PDF is prevalent, but accessing the textbook via authorized digital channels, using this ISBN, guarantees legitimate content and supports copyright regulations.

Beware of unauthorized downloads that may compromise quality or legality.

Publisher: McGraw-Hill Higher Education

McGraw-Hill Higher Education is the reputable publisher behind the 11th edition of “Humanities Through the Arts,” ensuring academic rigor and quality content. Seeking a free PDF version often leads to unreliable sources, potentially violating copyright.

Purchasing directly from McGraw-Hill or authorized retailers guarantees access to the complete, accurate textbook.

Supporting the publisher supports continued educational resource development and ethical content distribution, avoiding risks associated with unauthorized downloads.

Features of the Textbook

Interactive elements and detailed discussions enhance learning, while a focus on contemporary arts and values provides a modern perspective.

Beware of incomplete or altered PDFs found online, lacking these crucial textbook features.

Interactive Elements and Responses

The 11th edition distinguishes itself through engaging interactive elements, fostering a deeper understanding of complex artistic concepts. These features encourage critical thinking and active participation with the material, going beyond passive reading.

However, illegally obtained PDF versions often lack these crucial interactive components, diminishing the learning experience. Genuine access through VitalSource or legitimate channels ensures full functionality and a richer educational journey. Beware of compromised PDFs that offer a substandard substitute.

Detailed Discussions of Artistic Problems

This edition excels in its thorough examination of artistic challenges, providing nuanced perspectives on complex works and movements. It doesn’t shy away from difficult questions, encouraging students to grapple with ambiguity and interpretation.

Illegitimate PDF downloads frequently omit these in-depth analyses, offering a superficial understanding of the subject matter. Authentic access, whether print or through VitalSource, guarantees the complete and insightful discussions intended by the authors. Protect your learning by choosing legitimate sources.

Focus on Contemporary Arts and Values

The 11th edition significantly emphasizes modern artistic expressions, reflecting current cultural dialogues and societal shifts. It explores how contemporary art responds to pressing issues, fostering critical thinking about values and beliefs.

Beware of incomplete PDFs circulating online; they often lack the updated content crucial for understanding today’s art world. Genuine access, through authorized channels, ensures exposure to these vital contemporary perspectives. Prioritize legitimate sources to fully benefit from this edition’s relevance.

Academic Relevance

This textbook supports humanities disciplines – history, philosophy, literature, and cultural studies – offering a broad foundation for academic exploration and research.

Accessing a legitimate PDF ensures students receive the complete, scholarly content necessary for coursework and critical analysis.

Humanities Disciplines Included

The 11th edition’s scope encompasses a wide array of humanities fields, including history, providing context for artistic movements, and philosophy, exploring the underlying ideas shaping creative expression.

Religion’s influence on art is also examined, alongside languages and literatures, revealing how storytelling and poetic forms intertwine with visual and performing arts.

Furthermore, media and cultural studies are integrated, analyzing art’s role in contemporary society and its reflection of evolving values, making the PDF a versatile academic resource.

History, Philosophy, and Religion

The textbook intricately links historical events to artistic creation, demonstrating how societal shifts influence style and subject matter. Philosophical concepts are explored through art, revealing how artists grapple with existential questions and ethical dilemmas.

Religious themes and iconography are analyzed, showcasing the profound impact of faith on artistic expression across cultures and time periods.

The 11th edition PDF offers a nuanced understanding of these interconnected disciplines, enriching the appreciation of art’s cultural significance.

Languages and Literatures

The textbook examines how literature inspires and informs visual and performing arts, revealing shared themes and narrative structures; Analysis extends to the original languages of key texts, enriching understanding of artistic intent and cultural context.

Poetry, prose, and drama are explored as artistic mediums, demonstrating their influence on other art forms.

Accessing the 11th edition PDF facilitates a deeper exploration of these linguistic and literary connections, enhancing appreciation for artistic expression.

Media and Cultural Studies

The 11th edition integrates modern media, including film, into the broader humanities framework, analyzing its artistic merit and cultural impact. It explores how media shapes perceptions and reflects societal values, fostering critical thinking.

Cultural studies reveal the interplay between art, society, and power structures, offering insights into contemporary issues.

A PDF version of the textbook provides accessible resources for studying these dynamic relationships, enhancing understanding of artistic expression within a cultural context.

Using the Textbook for Study

Utilize effective reading and note-taking, focusing on key concepts within the PDF. Prepare thoroughly for assignments and exams using the textbook’s resources.

Effective Reading Strategies

Engage actively with the “Humanities Through the Arts” 11th edition PDF by previewing chapters and formulating questions beforehand. Focus on understanding core arguments and supporting evidence presented within each section.

Employ techniques like highlighting and annotation to mark key passages and concepts. Break down complex ideas into smaller, manageable parts for better comprehension. Regularly summarize sections to reinforce learning and identify areas needing further review.

Consider the historical and cultural context of artworks discussed, enhancing your analytical skills. Utilize the textbook’s interactive elements to deepen engagement and solidify understanding.

Note-Taking and Summarization Techniques

When studying the “Humanities Through the Arts” 11th edition PDF, utilize the Cornell method for organized note-taking – cues, notes, and summaries. Focus on capturing key themes, artistic styles, and historical contexts discussed.

Summarize each section in your own words, condensing complex ideas into concise statements. Create mind maps to visually represent relationships between concepts and artworks. Employ outlining to structure information hierarchically, aiding recall.

Regularly review and refine your notes, ensuring clarity and completeness for effective exam preparation.

Preparing for Exams and Assignments

Utilizing the “Humanities Through the Arts” 11th edition PDF, practice identifying artistic styles, symbolism, and cultural contexts. Review interactive elements and detailed discussions to anticipate potential exam questions.

For assignments, focus on analyzing artworks and relating them to societal values. Craft well-structured essays demonstrating comprehension of key concepts. Utilize note summaries and mind maps for efficient revision.

Consider forming study groups to discuss challenging topics and enhance understanding. Always cite sources properly to avoid plagiarism.

Loose Leaf Edition Availability

A cost-effective alternative, the loose-leaf version offers flexibility. However, accessing a free PDF remains a concern due to copyright restrictions and potential risks.

Benefits of the Loose Leaf Format

The loose-leaf edition presents a compelling alternative to traditional textbooks, offering significant cost savings for students seeking affordable access to “Humanities Through the Arts.” While a free PDF version is often desired, it raises ethical and legal concerns regarding copyright.

This format allows for customized organization, enabling students to arrange chapters according to their learning preferences and supplement with personal notes easily. It’s also lighter for carrying to class, reducing physical strain.

However, it requires a binder, which is a separate purchase, and the pages are more susceptible to damage or loss compared to a bound textbook. Despite these drawbacks, the economic advantage remains a key benefit.

Cost Considerations

The pursuit of a free PDF version of “Humanities Through the Arts” 11th edition is often driven by cost concerns, as textbooks can represent a substantial financial burden for students. However, accessing copyrighted material without proper payment is illegal and unethical.

Legitimate options, like the loose-leaf edition (ISBN: 9781264360192), offer a more affordable alternative to the traditional bound textbook. Digital versions via VitalSource (ISBNs: 9781264360215, 1264360215) also present cost-effective solutions.

While unauthorized downloads may seem appealing, they carry risks and undermine the authors’ and publishers’ rights. Investing in a legal copy supports the creation of future educational resources.

Copyright and Ethical Considerations

Respecting intellectual property is crucial; unauthorized PDF downloads violate copyright laws. Ethical academic practice demands legally obtained materials for study and research.

Respecting Intellectual Property

The pursuit of a free PDF of “Humanities Through the Arts” 11th Edition must not compromise ethical standards. Copyright laws protect the authors, Lee Jacobus and F. David Martin, and publisher, McGraw-Hill Higher Education.

Downloading from unauthorized sources constitutes a violation, undermining the creative process and potentially exposing users to risks. Legitimate access through purchase or institutional subscriptions supports continued scholarship and ensures the integrity of academic resources.

Prioritizing legal avenues demonstrates respect for intellectual property rights.

Avoiding Plagiarism

Accessing a “Humanities Through the Arts” 11th Edition PDF, even legally, doesn’t negate the need for original work. Submitting content sourced directly from the textbook without proper attribution constitutes plagiarism, a serious academic offense.

Always paraphrase ideas and cite sources meticulously, including page numbers when referencing specific passages. Utilizing the textbook’s insights requires thoughtful analysis and synthesis, demonstrating your understanding, not simply replicating its content.

Maintain academic honesty and integrity in all assignments.

Updates and Revisions in the 11th Edition

The 11th edition features new artworks and revised discussions, enhancing its exploration of contemporary arts and values, despite PDF access concerns.

New Artworks and Examples

The 11th edition significantly expands its visual and artistic repertoire, incorporating contemporary pieces alongside established classics to illustrate evolving cultural values. This update aims to provide students with a broader understanding of artistic expression across time periods and mediums.

While seeking a “Humanities Through the Arts” 11th edition PDF, users will find the revised content offers fresh perspectives. New examples enhance discussions of style, technique, and symbolism, enriching the learning experience and fostering critical analysis.

These additions reflect current artistic trends, ensuring the textbook remains relevant and engaging for today’s students.

Revised Discussions of Key Concepts

The 11th edition refines core concepts like cultural context and artistic style, offering nuanced explanations and updated interpretations. These revisions address contemporary scholarship and evolving understandings within the humanities.

Searching for a “Humanities Through the Arts” 11th edition PDF reveals that discussions on symbolism and the role of art in society have been thoroughly revisited.

The textbook now presents a more dynamic and inclusive exploration of these themes, fostering deeper critical thinking and a more comprehensive grasp of the subject matter.