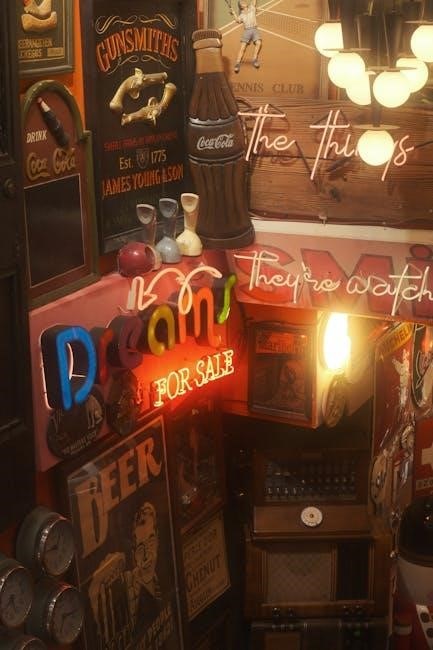

Coca-Cola Collectibles Price Guide: An Overview

Coca-Cola memorabilia’s enduring appeal fuels a vibrant collecting market, spanning bottles, signs, and promotional items․

Values fluctuate based on rarity, condition, and historical significance, offering diverse price points for enthusiasts․

Coca-Cola collecting represents a fascinating journey through American culture, advertising history, and design evolution․ What began as a simple beverage has blossomed into a global phenomenon, leaving behind a rich trail of collectible items․ The appeal lies not only in the nostalgic value but also in the potential for investment, as certain pieces appreciate significantly over time․

The hobby attracts a diverse range of collectors, from those seeking specific items like vintage bottles to those focused on complete sets of advertising materials․ Understanding the factors influencing value – condition, rarity, and historical context – is crucial for both novice and experienced collectors․ The market is dynamic, influenced by trends, auctions, and online marketplaces․ Exploring this world reveals a captivating blend of artistry, commerce, and cultural significance, making Coca-Cola collectibles a truly rewarding pursuit․

The History of Coca-Cola Collectibles

Coca-Cola’s collectible journey began almost concurrently with its 1886 inception, initially through promotional materials distributed to pharmacies․ Early items, like syrup dispensers and Hutchinson bottles, are now highly sought after due to their scarcity and historical significance․ The introduction of iconic contour bottles in 1915 marked a turning point, establishing a recognizable form that fueled collecting․

The early to mid-20th century witnessed an explosion of Coca-Cola advertising – tin signs, cardboard displays, and serving trays – becoming commonplace and, subsequently, collectible․ Post-war prosperity further expanded the range, with the addition of coolers, vending machines, and holiday-themed items․ Today, the market encompasses over a century of memorabilia, reflecting evolving tastes and marketing strategies․ Understanding this historical progression is key to appreciating the value and context of each collectible piece․

Bottles: A Collector’s Focus

Coca-Cola bottles represent a core collectible category, with value driven by age, rarity, and variations․ Early Hutchinson and contour bottles command premium prices among enthusiasts․

Early Hutchinson Bottles (1890s-1910s) ⎻ Pricing & Rarity

Hutchinson bottles, the earliest form of Coca-Cola packaging, are highly sought after by collectors due to their limited production run and historical significance․ These bottles, characterized by a unique stopper system, represent the dawn of the brand’s bottling era․ Pricing varies dramatically based on several factors, including the bottle’s condition, embossing clarity, and regional variations․

Bottles in pristine condition, exhibiting minimal wear and clear embossing, can fetch prices ranging from several hundred to over a thousand dollars․ Rarer variations, such as those from smaller, less-known bottling plants, or those with unique embossing errors, command even higher premiums․ Condition is paramount; chips, cracks, or significant wear substantially reduce value․ The presence of the original stopper further enhances collectibility and price․ Determining authenticity is crucial, as reproductions exist, so careful examination and research are essential for any prospective buyer or seller․

Straight-Sided Bottles (1915-1950s) ー Value Factors

Straight-sided Coca-Cola bottles, produced from the 1915 to the 1950s, represent a transitional period in the brand’s packaging history and offer a diverse range of collectible opportunities․ Their value is influenced by a combination of factors, including regional variations, bottling plant codes, and the presence of specific markings or logos․ Bottles from smaller, regional bottling companies generally command higher prices due to their limited distribution․

Condition remains a critical determinant of value; bottles free from chips, cracks, or significant staining are more desirable․ Variations in glass color – amber, clear, and green – also impact pricing, with certain colors being rarer than others․ The clarity and completeness of the embossed lettering contribute to a bottle’s appeal․ Furthermore, bottles still containing their original caps or labels significantly increase their worth, offering a glimpse into the past and enhancing their collectibility for enthusiasts․

Contour Bottles (1915-Present) ー Identifying Variations

The iconic Contour bottle, introduced in 1915, presents a vast and complex field for collectors․ Identifying variations is key to determining value․ Early versions, particularly those from the first few years of production, are highly sought after․ Look for subtle differences in the bottle’s shape, the embossing of the Coca-Cola logo, and the glass color – early bottles often exhibit a unique greenish tint․

Variations also arise from different bottling plants and production runs․ Collectors meticulously document these differences, noting variations in the base markings and the presence of specific mold flaws; Limited-edition bottles released for special events or promotions also command premium prices․ Understanding these nuances – from subtle shape changes to commemorative designs – is crucial for accurately assessing the worth of a Contour bottle and appreciating its place in Coca-Cola history․

Foreign Coca-Cola Bottles ⎻ Regional Values

Coca-Cola bottles from outside the United States often present unique collecting opportunities, with regional values significantly differing from domestic counterparts․ Bottles produced in countries with limited distribution or during specific political periods tend to be rarer and more valuable․ European bottles, particularly those from the post-war era, are highly sought after, as are those from South America and Asia․

Factors influencing value include the bottle’s condition, the presence of original labels (in good condition), and the overall scarcity within that specific region․ Bottles featuring local language variations of the Coca-Cola logo or unique bottle shapes specific to a country command higher prices․ Researching the bottling history of each country and understanding the local market demand is essential for accurate valuation․ Collectors often specialize in bottles from a particular region, developing expertise in identifying key variations and assessing their worth․

Advertising: Signs, Trays & More

Coca-Cola advertising pieces—signs, trays, and clocks—are highly collectible․ Price hinges on condition, scarcity, and design appeal, reflecting decades of marketing history․

Tin Signs ⎻ Condition & Scarcity Impacting Price

Coca-Cola tin signs represent a cornerstone of collectible advertising, with pricing heavily influenced by both condition and rarity․ Pristine signs, exhibiting minimal wear, vibrant colors, and original gloss, command significantly higher values than those displaying rust, fading, or damage․ Even minor imperfections can substantially reduce a sign’s worth․

Scarcity plays an equally crucial role․ Limited-edition signs, those produced for a short period, or those associated with specific promotions are naturally more sought after․ Early signs, particularly those from the late 19th and early 20th centuries, are exceptionally valuable due to their age and limited survival rates․ Signs featuring unique artwork or slogans also tend to fetch premium prices․

Collectors meticulously assess signs for authenticity, looking for original mounting holes, correct paint application, and consistent branding․ Repainted or restored signs generally hold less value than those in original condition․ Understanding these factors is essential for accurately evaluating and pricing Coca-Cola tin signs within the collectibles market․

Cardboard Signs ⎻ Grading and Preservation

Coca-Cola cardboard signs, while visually appealing, are inherently fragile, making grading and preservation paramount to maintaining value․ A standardized grading system, similar to those used for comic books, assesses condition – ranging from “Mint” (flawless) to “Poor” (significant damage)․ Even slight creases, edge wear, or fading can dramatically lower a sign’s worth․

Preservation is key․ Proper storage in acid-free sleeves and flat, dry environments protects against further deterioration․ Exposure to light, moisture, and fluctuating temperatures accelerates damage․ Professional restoration, while possible, often diminishes collectible value if not expertly executed․ Collectors generally prefer original, unrestored signs․

Rarity also influences price; limited-run or promotional cardboard signs are highly desirable․ Signs advertising specific events or featuring unique artwork command premiums․ Careful examination for authenticity – verifying printing techniques and paper stock – is crucial when evaluating these delicate pieces of Coca-Cola history․

Serving Trays ー Popular Designs & Market Value

Coca-Cola serving trays represent a significant segment of the collectibles market, prized for their vibrant artwork and nostalgic appeal․ Early trays, particularly those from the 1910s to 1940s, featuring pin-up girls, scenic landscapes, and iconic Coca-Cola branding, are highly sought after by collectors․

Market value is heavily influenced by design rarity, condition, and year of production․ Trays in excellent condition, retaining their original gloss and free from scratches or fading, command higher prices․ Certain designs, like the 1913 “Gibson Girl” tray or those featuring holiday themes, are particularly valuable․

Later trays, while still collectible, generally fetch lower prices․ Factors like tray material (metal versus plastic) and size also play a role․ Authenticity is crucial; reproductions exist, so verifying markings and construction details is essential for accurate valuation within the Coca-Cola collecting world․

Advertising Clocks ⎻ Functionality & Collectibility

Coca-Cola advertising clocks are highly desirable collectibles, blending functionality with iconic branding․ These clocks, primarily produced from the 1930s through the 1970s, were originally used in diners, soda fountains, and retail establishments to promote the beverage․

Value is significantly impacted by working condition; a fully functional clock commands a premium․ Rarity of the specific design also plays a crucial role, with limited-edition or prototype clocks being exceptionally valuable․ Condition is paramount – original paint, minimal wear, and intact glass contribute to higher prices․

Clocks featuring distinctive shapes, such as the iconic bottle-shaped clocks, are particularly sought after․ Authenticity is key, as reproductions exist․ Collectors carefully examine markings, movement mechanisms, and overall construction to ensure genuineness within the Coca-Cola memorabilia market․

Promotional Items: Beyond Bottles & Signs

Coca-Cola’s extensive promotional range—vending machines, coolers, toys—offers diverse collecting opportunities․ Value hinges on rarity, condition, and the item’s connection to Coca-Cola’s history․

Coca-Cola Vending Machines ⎻ Restoration & Worth

Coca-Cola vending machines represent a significant segment of the collectibles market, prized for their iconic design and historical representation of beverage distribution․ Early, pre-1960s machines, particularly those in original condition, command the highest prices․ Restoration plays a crucial role in determining value; a fully functional machine with original paint and decals will far exceed the price of one requiring extensive work․

Worth is heavily influenced by model rarity․ Machines like the Cavalier and the early upright models are highly sought after․ A meticulously restored Cavalier machine could fetch several thousand dollars, while common models in poor condition might only be worth a few hundred․ The cost of restoration – including parts, paint, and professional labor – must be factored into any potential purchase or sale․ Collectors often specialize in restoring these machines, adding significant value through their expertise․ Assessing the machine’s operational status, cosmetic condition, and originality is paramount when determining its market value․

Coolers & Ice Chests ー Vintage Appeal & Pricing

Coca-Cola coolers and ice chests are highly desirable collectibles, embodying a nostalgic era of roadside refreshment․ Their value hinges on age, condition, and rarity of design․ Early, porcelain-clad coolers from the 1930s-1950s, especially those with intact branding, command premium prices, often exceeding several thousand dollars․ Metal ice chests from the mid-20th century also hold significant appeal, with prices ranging from a few hundred to over a thousand depending on condition and model․

Restoration can increase value, but originality is often preferred by serious collectors․ Rust, dents, and faded paint will lower the price, while a fully functional cooler with original parts is a prized find․ Limited-edition coolers or those featuring unique promotional artwork are particularly valuable․ Assessing the cooler’s structural integrity, the clarity of the branding, and the presence of any original components are key factors in determining its worth within the collectibles market․

Holiday Collectibles (Santa, Christmas) ー Seasonal Demand

Coca-Cola’s association with Santa Claus, solidified through iconic advertising campaigns, makes holiday collectibles exceptionally popular․ Demand surges seasonally, particularly leading up to Christmas, driving up prices․ Vintage Santa Claus figures adorning Coca-Cola bottles or featured on promotional materials are highly sought after, with rarer pieces fetching substantial sums․

Early Christmas-themed trays, ornaments, and advertising signs can range from $50 to several hundred dollars, depending on condition and scarcity․ Limited-edition holiday sets and promotional items released in recent decades also gain value over time․ Condition is paramount; pristine items command higher prices․ Collectors actively seek out pieces that evoke the classic Coca-Cola Christmas imagery․ The presence of original packaging further enhances value․ Careful evaluation of authenticity and condition is crucial when assessing these festive collectibles․

Coca-Cola Toys & Premiums ⎻ Character & Rarity

Coca-Cola toys and premiums represent a diverse and engaging category for collectors․ Character-based items, featuring recognizable figures or mascots, often command higher prices․ Early promotional toys, distributed as incentives with Coca-Cola purchases, are particularly valuable due to their limited production runs and historical significance․

Rarity is a key driver of value; unique or hard-to-find toys can fetch substantial sums at auction․ Condition plays a crucial role, with mint-in-box items commanding the highest prices․ Examples include vintage plush toys, metal figurines, and promotional vehicles․ Even seemingly simple premiums, like bottle caps with unique designs, can be collectible․ Identifying original packaging and verifying authenticity are essential steps in evaluating these items․ The appeal lies in both the nostalgic charm and the collectible nature of these Coca-Cola branded toys․

Specific Collectible Categories

Coca-Cola’s diverse offerings extend beyond bottles and signs, encompassing syrup dispensers, crates, employee items, and calendars․

Each category presents unique valuation factors based on originality and condition․

Coca-Cola Syrup Dispensers ー Historical Significance & Value

Coca-Cola syrup dispensers represent a fascinating chapter in the brand’s history, initially utilized in soda fountains during the late 19th and early 20th centuries․ These ornate dispensers weren’t simply functional; they were powerful advertising tools, prominently displaying the Coca-Cola logo and contributing to the brand’s growing recognition․ Their historical significance directly impacts their collector value․

Early, hand-painted porcelain or metal dispensers command the highest prices, often reaching several thousand dollars, particularly if they retain original pumps and spouts․ Factors influencing value include the dispenser’s size, the clarity of the logo, and overall condition․ Restoration can decrease value if not expertly executed․ Later, mass-produced dispensers, while more common, still hold appeal for collectors, especially those in excellent condition․

Variations in design, such as different fonts or decorative elements, can also affect pricing․ Identifying the manufacturer and the specific era of production is crucial for accurate valuation․ Online auction sites and specialized Coca-Cola collecting guides are invaluable resources for researching current market values․

Coca-Cola Crates & Carriers ⎻ Originality & Condition

Coca-Cola crates and carriers, essential for transporting bottles during the brand’s early distribution, are highly sought-after collectibles․ Their value hinges significantly on originality and condition; Early wooden crates, particularly those with pre-1920s branding, are exceptionally desirable, often fetching substantial prices at auction․

Condition is paramount; crates exhibiting minimal wear, original paint, and intact labeling command premium values; Significant damage, such as broken slats or extensive fading, drastically reduces worth․ Carriers, including both wooden and wire versions, also follow this principle․ Those used to deliver Coca-Cola to homes and businesses are especially prized․

Authenticity is crucial․ Collectors scrutinize for correct logos, fonts, and construction techniques․ Reproductions are common, so careful examination is vital․ Researching specific crate variations and markings using online databases and collecting guides helps determine genuine articles and their corresponding market value․ A well-preserved, original crate can be a centerpiece of any Coca-Cola collection․

Coca-Cola Employee Items ⎻ Limited Edition & Price

Coca-Cola employee items represent a unique and often overlooked segment of the collectibles market․ These pieces, originally distributed to company staff, are typically produced in limited quantities, contributing to their desirability and value․ Examples include commemorative pins, vests, serving pieces, and even early promotional materials not widely available to the public․

The price of these items is heavily influenced by rarity and the item’s connection to significant company milestones․ Items tied to anniversaries, special events, or specific departments often command higher prices․ Condition plays a vital role, with pristine, unused items fetching the most substantial sums․

Authenticity is key; verifying that an item was genuinely issued to an employee requires careful research․ Documentation, such as employee records or internal memos, can bolster provenance․ Online resources and experienced collectors can assist in authentication․ Due to their limited availability, Coca-Cola employee items are often considered investment-grade collectibles․

Coca-Cola Calendars ー Year & Artwork Influence

Coca-Cola calendars are highly sought-after collectibles, prized for their vibrant artwork and historical representation of the brand’s advertising evolution․ Their value is significantly impacted by the year of production and the artist featured․ Early 20th-century calendars, particularly those with illustrations by renowned artists like N․C․ Wyeth or Gil Elvgren, command premium prices․

Calendars from years marked by significant historical events or featuring unique promotional campaigns also tend to be more valuable․ Condition is paramount; calendars in excellent, undamaged condition, retaining their original vibrancy, are worth considerably more than those with wear and tear․

The artwork itself plays a crucial role․ Calendars showcasing iconic imagery, such as the beloved Santa Claus depictions, are particularly popular․ Collectors often specialize in specific artists or eras, driving demand and influencing market values․ Careful preservation, including protection from light and humidity, is essential for maintaining a calendar’s collectible worth․

Evaluating Your Collection

Assessing your Coca-Cola collection requires careful condition grading, authenticity checks, and thorough price research using online databases and guides to determine value․

Condition Grading ⎻ A Standard Approach

Condition is paramount when evaluating Coca-Cola collectibles, significantly impacting their market value․ A standardized grading system helps collectors and sellers establish a common understanding․ Mint condition items, exhibiting no flaws or wear, command the highest prices․ Near Mint pieces show only the slightest imperfections, barely noticeable upon close inspection․

Excellent condition indicates minor wear consistent with age, such as slight fading or small scratches․ Good condition reveals noticeable wear, including scratches, dents, or paint loss, but the item remains structurally sound․ Fair condition signifies substantial wear and tear, potentially affecting functionality or aesthetics․ Poor condition items are heavily damaged and typically have limited value, unless exceptionally rare․

Grading considers factors like paint integrity on signs, clarity of glass on bottles, and the presence of original labels․ Restoration, while sometimes necessary, generally diminishes value unless expertly done․ Accurate condition assessment is crucial for fair pricing and successful transactions within the Coca-Cola collecting community․

Determining Authenticity ⎻ Spotting Fakes

The popularity of Coca-Cola collectibles unfortunately attracts counterfeiters․ Authenticating items requires careful scrutiny․ Examine manufacturing details – original pieces typically exhibit consistent quality and precise markings․ Be wary of overly “perfect” items, as genuine vintage pieces usually show some signs of age and wear․

Research specific variations; knowing the correct fonts, colors, and materials for a particular era is vital․ Compare the item to known authentic examples using online resources and price guides․ Pay attention to labels and logos – inconsistencies are red flags․ Inspect for reproduction stamps or markings attempting to mimic age․

Consider the source․ Purchasing from reputable dealers or established auction houses minimizes risk․ If a deal seems too good to be true, it likely is․ Familiarize yourself with common faking techniques and seek expert opinions when uncertain․ Protecting yourself from fraudulent items ensures a rewarding collecting experience․

Resources for Price Research ー Online Databases & Guides

Accurately pricing Coca-Cola collectibles demands thorough research; Several online resources provide valuable data․ Online auction sites like eBay offer completed sales records, revealing actual market values․ Dedicated Coca-Cola collecting websites and forums host price databases and expert discussions․

Specialized price guides, both online and in print, catalog various items with estimated values based on condition and rarity․ The Corpus of Contemporary American English (COCA), while not solely focused on collectibles, demonstrates the brand’s enduring presence and collector interest․

Remember to cross-reference information from multiple sources․ Condition significantly impacts price, so assess your item carefully․ Consider joining collecting communities for access to shared knowledge and expert appraisals․ Staying informed about current market trends is crucial for both buyers and sellers․

Selling Your Coca-Cola Collectibles ー Options & Strategies

When selling Coca-Cola collectibles, several avenues exist․ Online auction platforms like eBay reach a broad audience, but require careful listing and shipping․ Dedicated online marketplaces specializing in vintage items can attract serious collectors․ Local antique shops and consignment stores offer convenience, though potentially lower returns․

Attending collectibles shows and flea markets allows direct interaction with potential buyers․ Consider the item’s condition and rarity when setting a price, referencing recent sales data․ High-quality photographs are essential for online listings․

Be prepared to negotiate, and factor in shipping costs․ For valuable items, professional appraisal may be worthwhile․ Patience is key; finding the right buyer can maximize your profit․ Properly packaging items is crucial to prevent damage during transit․