This manual serves as a creative guide, offering insights into Nazarene beliefs and practices, mirroring a journey alongside the historical Jesus.

It’s a Christian resource, emphasizing Scripture and providing a pathway for understanding the Nazarene tradition’s enduring relevance today.

Exploring the historical context, this manual delves into the origins of Nazarene guides and their significance within Jewish Christianity.

Historical Context of Nazarene Manuals

The roots of Nazarene manuals are deeply intertwined with the earliest expressions of Christian faith, specifically within the context of first-century Jewish Christianity. Emerging from the end of the New Testament period, these early guides sought to define and preserve the unique identity of those who followed the teachings of Jesus of Nazareth.

Initially, this wasn’t a formalized, written tradition, but rather a lived practice passed down through generations, motivated by both faith and perceived practical benefits. The concept of a “Nazarene” itself carries historical weight, referencing Jesus’s hometown and, by extension, his followers.

Over time, the need to articulate and codify these beliefs grew, leading to the development of instructional materials. These early manuals, though perhaps not surviving in their original form, laid the groundwork for later compilations; The study of the historical Jesus, as evidenced by resources like the Handbook for the Study of the Historical Jesus, informs our understanding of this period.

The evolution of these guides reflects a continuous effort to maintain doctrinal purity and practical guidance for adherents.

Purpose and Scope of the Manual

This Nazarene Manual serves as a comprehensive resource, designed to illuminate the beliefs, practices, and historical foundations of this unique Christian tradition. Its primary purpose is to guide individuals on a journey of faith, offering a deeper understanding of the Nazarene walk and its connection to the life of Jesus.

The scope encompasses both theological exploration and practical application, including guidance on devotional practices, worship, and community engagement. A key element is the exploration of the Nazarene Vow, examining its meaning and historical precedents, such as the example of Samson.

Furthermore, the manual provides tools for practical endeavors, like banner design and construction, alongside basic mathematical calculations and resources for further study in algebra and calculus. It aims to equip believers with both spiritual insight and practical skills.

Ultimately, this manual seeks to bridge the gap between historical understanding and contemporary relevance.

Core Beliefs and Doctrines

Central to Nazarene faith are foundational Christian tenets, coupled with specific theological perspectives rooted in Scripture and historical Jesus studies.

These doctrines shape worship, devotional life, and the understanding of the Nazarene vow’s significance.

Foundational Christian Beliefs

The bedrock of Nazarene belief rests firmly upon the core tenets of traditional Christianity. This includes a profound conviction in the Triune God – Father, Son (Jesus Christ), and Holy Spirit – each distinct yet unified in divine essence.

Central is the belief in Jesus Christ as the Messiah, fully God and fully human, whose sacrificial death on the cross provides atonement for humanity’s sins. Resurrection affirms victory over death and offers eternal life to those who believe.

Further foundational beliefs encompass the authority of the Bible as the inspired Word of God, the importance of grace through faith, and the necessity of repentance and discipleship. These principles guide moral conduct and spiritual growth, forming the ethical framework for Nazarene life and practice.

These beliefs are not merely intellectual assent, but transformative truths meant to be lived out daily, shaping character and fostering a deep relationship with God.

Specific Nazarene Theology

Nazarene theology, while deeply rooted in mainstream Christianity, possesses unique emphases. A key distinction lies in its holistic approach to salvation, stressing not only spiritual redemption but also the pursuit of Christian perfection – a lifelong journey of growth in grace.

This pursuit isn’t understood as achieving flawless sinlessness, but as a progressive conformity to the image of Christ, empowered by the Holy Spirit. Sanctification, therefore, is a central theme, impacting daily life and ethical considerations.

Furthermore, Nazarenes hold a particular reverence for the historical Jesus, seeking to understand His life and teachings within their first-century Jewish context. This informs their interpretation of Scripture and their commitment to social justice.

The emphasis on practical holiness, coupled with a commitment to biblical scholarship, defines the distinctive theological character of the Nazarene tradition.

The Role of Scripture in Nazarene Faith

Scripture occupies a central and authoritative position within Nazarene faith, viewed as the inspired Word of God and the ultimate guide for belief and practice. It’s not merely a historical document, but a living and relevant source of truth, capable of transforming lives.

Nazarenes embrace a hermeneutic that seeks to understand Scripture within its historical and literary context, recognizing the importance of both the original languages and the broader biblical narrative. Careful study and thoughtful interpretation are highly valued.

The Bible is considered foundational for understanding the life and teachings of Jesus, providing the lens through which all other experiences and knowledge are evaluated. It informs their devotional practices and ethical decision-making.

This commitment to Scripture is reflected in the Nazarene Manual’s emphasis on biblical literacy, encouraging believers to engage deeply with God’s Word and apply its principles to every aspect of their lives.

Nazarene Practices and Traditions

Nazarene life is characterized by devotional practices, prayer, and community, rooted in historical teachings and passed down through generations with faith.

Worship and liturgical practices reflect a deep reverence for God, while fostering a strong sense of belonging and shared purpose.

Devotional Practices and Prayer

Central to the Nazarene tradition are deeply ingrained devotional practices and a consistent life of prayer. These aren’t merely ritualistic observances, but expressions of a heartfelt connection with the Divine, motivated by both faith and the perceived practical benefits received over time.

The manual emphasizes that these practices stem directly from core church teachings, carefully passed down through generations, ensuring continuity and authenticity. Prayer, in particular, is viewed as a vital lifeline, fostering intimacy with God and providing guidance in daily life.

Furthermore, the manual suggests that consistent devotion isn’t simply about personal piety, but also about strengthening the communal bonds within the Nazarene fellowship. Shared prayer and devotional exercises cultivate a spirit of unity and mutual support, enriching the spiritual lives of all involved.

Worship and Liturgical Practices

The Nazarene Manual outlines worship and liturgical practices rooted in a blend of historical Jewish traditions and early Christian expressions. While specific forms may vary across communities, a common thread is a reverence for Scripture and a commitment to participatory worship.

Liturgical elements often include readings from the Old and New Testaments, responsive prayers, and the singing of hymns and spiritual songs. Emphasis is placed on creating an atmosphere conducive to encountering God’s presence and fostering a sense of collective devotion.

The manual acknowledges the importance of symbolism within worship, recognizing that rituals can serve as powerful reminders of core beliefs and spiritual truths. However, it cautions against allowing form to overshadow substance, stressing that genuine worship flows from a transformed heart.

The Significance of Community in Nazarene Life

The Nazarene Manual underscores that faith isn’t a solitary pursuit, but is profoundly shaped within the context of community. It highlights the importance of mutual support, accountability, and shared discipleship among believers.

This communal aspect stems from the early church model, where believers devoted themselves to fellowship, prayer, and breaking bread together. The manual emphasizes the practical benefits of community – providing encouragement during trials, offering wisdom in decision-making, and fostering spiritual growth.

Moreover, it recognizes that devotion is often passed down through generations, motivated by both faith and practical benefits; Community provides a space for this transmission of values and traditions, ensuring the continuity of the Nazarene way of life.

Understanding the Historical Jesus

The Nazarene Manual utilizes historical research, focusing on the Gospels to understand Jesus’ life and teachings with scholarly rigor and faith-based perspective.

It provides a guide for studying the historical Jesus, offering a deeper comprehension of his context and message.

Historical Research on Jesus

The Nazarene Manual emphasizes a rigorous approach to understanding Jesus, advocating for informed study utilizing available historical resources. This includes examining archaeological findings, analyzing ancient texts beyond the biblical canon, and considering the socio-political landscape of first-century Palestine.

It acknowledges the complexities inherent in reconstructing the historical Jesus, recognizing the challenges of separating historical fact from theological interpretation. The manual encourages critical engagement with scholarship, referencing works like the Handbook for the Study of the Historical Jesus published by Brill, to foster a nuanced understanding.

Furthermore, the manual promotes awareness of differing perspectives within historical Jesus studies, acknowledging the ongoing debates surrounding his life, ministry, and message. It aims to equip readers with the tools to evaluate evidence and form their own informed conclusions, grounded in both faith and reason.

Nazarene Perspectives on Jesus’ Life

The Nazarene Manual presents Jesus not merely as a historical figure, but as the central figure of salvation, deeply rooted in Jewish tradition yet fulfilling its prophetic promises. It emphasizes Jesus’ identity as a practicing Jew, understanding his life and teachings within the context of first-century Judaism.

This perspective highlights Jesus’ adherence to the Torah, his engagement with Jewish debates, and his proclamation of the Kingdom of God as a restoration of Israel. The manual stresses that Jesus’ ministry was a continuation of, not a rejection of, Jewish faith.

Moreover, it underscores the importance of the Gospels as primary sources, while acknowledging the theological frameworks shaping their narratives. The manual encourages readers to explore the Gospels seeking to understand Jesus’ life through the eyes of his earliest followers, recognizing their faith-based interpretations.

The Importance of the Gospels

The Nazarene Manual affirms the Gospels as foundational texts, providing the most comprehensive accounts of Jesus’ life, ministry, death, and resurrection. They are viewed not simply as historical records, but as faith-inspired testimonies revealing the divine nature and salvific purpose of Jesus Christ.

The manual encourages a careful reading of each Gospel, recognizing their unique perspectives and theological emphases. It acknowledges that the Gospel writers, guided by the Holy Spirit, selected and presented events to convey specific truths about Jesus.

Furthermore, the manual promotes utilizing resources like the “Handbook for the Study of the Historical Jesus” to deepen understanding. It stresses that while historical context is vital, the Gospels’ primary aim is to inspire faith and transform lives, offering a pathway to a relationship with God.

The Nazarene Vow and Samson

The manual explores the Nazarene vow, detailing its meaning, restrictions, and obligations, using Samson as a prime biblical example of this dedicated lifestyle.

Samson’s story, meaning “sunshine,” illustrates the commitments inherent in the vow, offering insights into its practical implications and spiritual significance.

The Meaning of Being a Nazarene

The Nazarene identity, as illuminated within this manual, transcends a mere set of rules; it embodies a dedicated path of holiness and separation unto God. This commitment, historically rooted in ancient Israel, signifies a deliberate choice to live a life consecrated to divine service, mirroring the Levitical priests’ dedication.

Being a Nazarene involves specific vows, often temporary, that dictate abstentions from certain practices – notably, refraining from consuming wine or strong drink, avoiding contact with corpses, and maintaining the untrimmed growth of hair. These aren’t arbitrary restrictions, but symbolic acts representing purity and devotion.

The manual emphasizes that the core of the Nazarene calling is a heart focused on God, expressed through disciplined living and unwavering faith. It’s a journey of self-denial, seeking a deeper relationship with the Divine, and demonstrating commitment through tangible actions. This dedication reflects a profound spiritual aspiration.

Samson as a Biblical Example of a Nazarene

This manual presents Samson as a pivotal figure, illustrating the practical implications of the Nazarene vow within a biblical context. His very name, meaning “sunshine,” hints at the radiant potential inherent in this dedicated lifestyle. Samson’s birth was foretold, designating him from infancy as a Nazarene, set apart for a special purpose ordained by God.

The manual highlights that Samson’s life vividly demonstrates both the blessings and the challenges of adhering to the Nazarene restrictions. While empowered by God, his struggles also reveal the consequences of compromising his vow, emphasizing the importance of unwavering obedience.

Examining Samson’s story, the manual underscores that the Nazarene commitment isn’t simply about outward observances, but about cultivating an inner devotion and recognizing God’s sovereignty. His narrative serves as a cautionary tale and an inspiring example of faith in action.

Restrictions and Obligations of the Nazarene Vow

This manual meticulously details the specific restrictions inherent in the Nazarene vow, extending beyond mere abstinence. It encompasses a holistic commitment to purity, impacting dietary choices, personal grooming, and social interactions. The vow demanded complete separation from anything that could defile the individual, maintaining a consecrated state for the duration.

The obligations weren’t solely negative; they also included positive duties, such as dedicated service in the temple and a commitment to lifelong devotion. This manual clarifies that the vow wasn’t a burden, but an opportunity for deeper communion with God, fostering spiritual growth and discipline.

Understanding these requirements, the manual emphasizes the seriousness of entering such a covenant, highlighting the need for careful consideration and unwavering commitment. It’s a pathway to holiness, demanding sacrifice and yielding profound spiritual rewards;

Practical Applications and Guidance

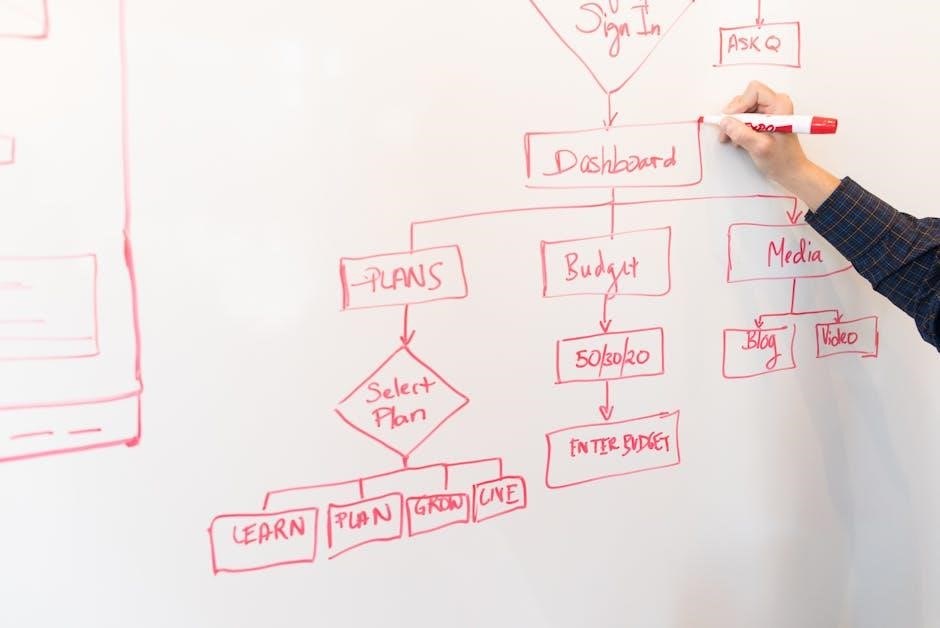

This section offers a handbook for banner design and construction, alongside basic mathematical tools – calculators for addition, subtraction, and more complex equations.

Resources include algebra and calculus support, aiding practical application of faith and knowledge in daily life.

Banner Design and Construction

Creating banners is a tangible expression of faith, a visual proclamation of Nazarene beliefs and values. This guide provides a creative framework for designing and constructing banners suitable for worship services, community events, or personal devotion.

Consider the symbolism of colors and imagery, drawing inspiration from Scripture and the natural world. Explore different materials – fabric, canvas, or even repurposed materials – to reflect the message you wish to convey.

The manual details construction techniques, from simple hand-sewn banners to more elaborate designs utilizing basic carpentry skills. Emphasis is placed on durability and visual impact, ensuring the banner effectively communicates its intended message. Handbook A, a dedicated resource, offers detailed instructions and design ideas.

Remember to prioritize clarity and simplicity, allowing the message to resonate with viewers of all ages and backgrounds. A well-crafted banner can serve as a powerful tool for evangelism and spiritual encouragement.

Basic Mathematical Calculations

While seemingly unrelated to spiritual practice, a foundational understanding of mathematics fosters discipline and logical thinking, qualities valued within the Nazarene tradition. This section provides a review of essential arithmetic operations – addition, subtraction, multiplication, and division.

Practical applications abound, from calculating offerings and tithes to managing resources for community outreach programs. Online calculators are readily available for quick computations, but mastering the fundamentals is crucial for deeper comprehension.

The manual includes exercises and examples, reinforcing core concepts and building confidence. Use this basic calculator online for assistance with these operations. It also covers percentages, square roots, and the use of pi, essential for various calculations.

Understanding these principles empowers individuals to approach challenges with clarity and precision, reflecting a commitment to stewardship and responsible living.

Algebra and Calculus Resources

For those seeking to expand their mathematical skillset, this section provides a gateway to more advanced concepts – algebra and calculus. These disciplines, while complex, cultivate abstract reasoning and problem-solving abilities, enriching one’s understanding of the world.

Resources are curated to support self-directed learning, including links to online platforms like QuickMath, which automatically solves common high school and college-level problems. Algebraic functions such as expansion and factorization are explored.

Calculus, the study of change, offers insights into dynamic systems and patterns. These tools are not merely academic exercises; they represent a commitment to intellectual growth and a deeper appreciation for the intricacies of creation.

Utilizing these resources fosters analytical thinking, enabling individuals to approach complex challenges with confidence and discernment.

Contemporary Relevance

Nazarene Christianity persists today, addressing modern challenges with enduring faith and scriptural guidance, shaping a future rooted in tradition and devotion.

The Nazarene tradition offers a unique perspective, fostering community and inspiring believers to live purposeful lives in a changing world.

Nazarene Christianity Today

Contemporary Nazarene Christianity represents a vibrant, yet often overlooked, stream within the broader Christian landscape. It’s characterized by a deep commitment to both historical roots and present-day relevance, seeking to embody the teachings and lifestyle of the first followers of Jesus.

This expression of faith emphasizes practical devotion, passed down through generations, motivated by both spiritual conviction and tangible benefits experienced in daily life. While firmly grounded in church teachings, it also encourages a personal and dynamic relationship with God.

Today, Nazarene communities are found globally, striving to live out their beliefs in diverse cultural contexts. They actively engage in social outreach, seeking to demonstrate the love of Christ through acts of service and compassion. The focus remains on a holistic faith, integrating worship, discipleship, and mission.

The enduring appeal of Nazarene Christianity lies in its authenticity, its emphasis on Scripture, and its commitment to living a life of purpose and integrity.

Addressing Modern Challenges

Modernity presents unique challenges to all faith traditions, and Nazarene Christianity is no exception. Issues like secularism, relativism, and the rapid pace of technological change demand thoughtful engagement and a renewed commitment to core values.

A key aspect of addressing these challenges involves fostering a critical and self-reflective approach to practice. This includes questioning assumptions, examining motivations, and ensuring that traditions remain relevant and meaningful in a changing world.

Furthermore, Nazarene communities must navigate complex ethical dilemmas arising from advancements in science and technology, while upholding biblical principles. Open dialogue, informed by Scripture and reason, is crucial for discerning wise and compassionate responses.

Ultimately, the strength of Nazarene Christianity lies in its ability to adapt without compromising its foundational beliefs, offering a compelling witness to the transformative power of faith in the 21st century.

The Future of the Nazarene Tradition

The future of the Nazarene tradition hinges on its capacity to remain both deeply rooted in its historical foundations and dynamically responsive to the evolving needs of the world. This requires a continued emphasis on devotional practices, community building, and a rigorous engagement with Scripture.

Embracing innovative approaches to discipleship and outreach, particularly leveraging digital platforms, will be essential for reaching new generations. Simultaneously, preserving the rich heritage of Nazarene worship and liturgical practices ensures continuity and spiritual depth.

A commitment to theological education and scholarship will equip future leaders to articulate the Nazarene faith with clarity and conviction. Fostering interfaith dialogue and collaborative partnerships will broaden the tradition’s impact and promote understanding.

Ultimately, the Nazarene tradition’s enduring legacy will depend on its ability to embody the love, grace, and transformative power of Jesus Christ in a world desperately seeking hope and meaning.

Resources and Further Study

Explore recommended reading materials, online studies, and helpful manuals, including guides on the Historical Jesus and resources for algebra and calculus.

QuickMath and online calculators provide practical assistance, while Brill publications offer scholarly insights into Nazarene Jewish Christianity.

Recommended Reading Materials

For a foundational understanding of Christian beliefs, Beyer D.’s “Basic Beliefs of Christians” provides a solid starting point. To delve specifically into the Nazarene tradition, seek out materials that explore Nazarene Jewish Christianity, tracing its development from the New Testament period onwards.

Scholarly works, such as the “Handbook for the Study of the Historical Jesus” published by Brill (Leiden and Boston), are invaluable for contextualizing the life and times of Jesus.

Additionally, consider resources that creatively guide banner design and construction – a practical aspect often associated with Nazarene practices. While not directly theological, these handbooks demonstrate the applied faith of the community. Remember to supplement these with materials offering basic mathematical calculations and resources for algebra and calculus, reflecting a holistic approach to learning.

Online Resources for Nazarene Studies

Numerous online platforms offer valuable tools for exploring Nazarene theology and history. Basic online calculators are readily available for mathematical needs, supporting practical applications of faith and potentially aiding in banner construction calculations.

QuickMath provides automated solutions for algebra, equations, and calculus problems, beneficial for students and researchers alike.

Furthermore, explore digital archives and scholarly databases for articles on Nazarene Jewish Christianity and the historical Jesus. Websites dedicated to Christian studies often feature resources on related topics. Be mindful of source credibility, as information accuracy varies online. Utilize these resources to supplement traditional reading materials and foster a deeper understanding of the Nazarene tradition, remembering to critically evaluate all information encountered.

Study Guides and Manuals

Complementing online resources, several study guides and manuals enhance Nazarene understanding. A “Creative Guide for Banner Design and Construction” provides practical application of faith principles, linking belief to tangible expression.

Dedicated handbooks focusing on the Historical Jesus offer in-depth research and diverse perspectives, crucial for contextualizing the Nazarene movement.

Exploring materials on foundational Christian beliefs and specific Nazarene theology builds a robust doctrinal framework. Remember to seek resources that emphasize Scriptural interpretation and historical accuracy. These guides facilitate both individual study and group discussions, fostering a deeper connection to the tradition and its practices. Utilizing these tools alongside online resources creates a comprehensive learning experience, enriching one’s understanding of the Nazarene path.