High mountain summer sausage is a traditional, flavorful delicacy, perfect for hearty suppers. Made with premium meats and spices like fennel seeds, it offers a rich, savory taste experience.

Overview of High Mountain Summer Sausage

High Mountain Summer Sausage is a flavorful, traditionally crafted delicacy known for its rich taste and versatility. Made with premium meats and spices, it offers a savory experience. Fennel seeds add a fresh, mildly peppery flavor, balancing the hearty meat. This sausage is perfect for hearty suppers, snacks, or charcuterie boards, making it a popular choice for various occasions. Its traditional roots and modern adaptations ensure it remains a beloved option for many.

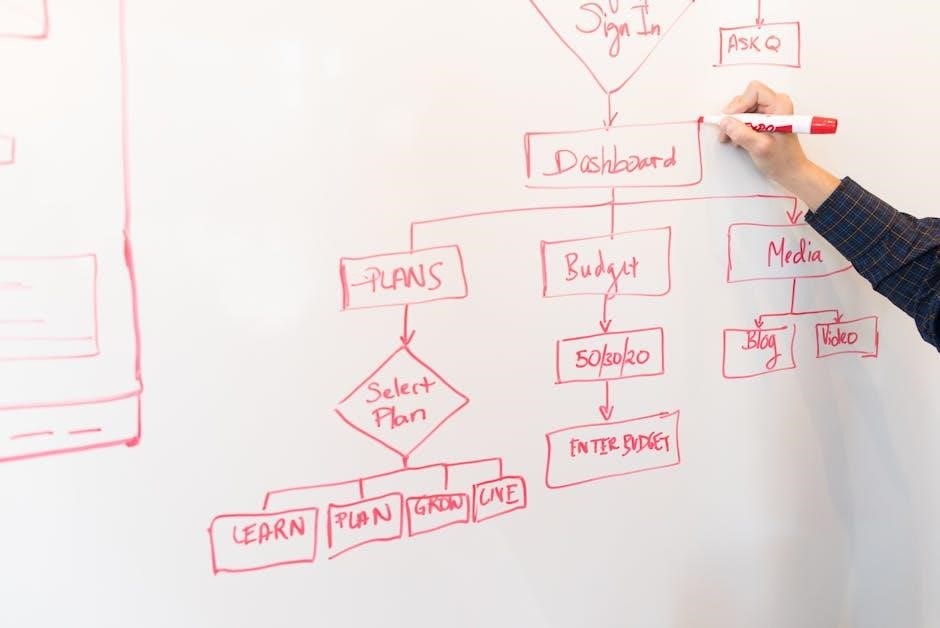

Importance of Proper Instructions

Proper instructions are crucial for crafting High Mountain Summer Sausage to ensure safety, quality, and consistency. Following precise steps guarantees the meat is handled safely, flavors are balanced, and textures are preserved. This attention to detail prevents issues like mold or dryness, ensuring a delicious and durable final product. Adhering to instructions also maintains the sausage’s traditional appeal, making it a reliable choice for various culinary uses. Proper techniques are key to achieving the perfect blend of spices, like fennel seeds, which enhance the sausage’s distinctive flavor profile.

Ingredients and Supplies

High-quality meats, spices like garlic and pepper, and casings are essential. Additional supplies include a meat grinder, sausage stuffer, and seasonings like fennel seeds for flavor.

Meat Selection and Preparation

Selecting the right meats is crucial for high mountain summer sausage. Typically, a combination of beef, pork, and venison is used for optimal flavor and texture. Ensure meats are fresh and chilled before grinding. A 70-30 lean-to-fat ratio is ideal for juiciness. Trim any excess fat or connective tissue to avoid bitterness. Grind meats finely and mix thoroughly with seasonings. Keep ingredients cold throughout preparation to maintain consistency and prevent spoilage. Proper handling ensures a safe and delicious final product.

Spices and Seasonings

High mountain summer sausage relies on a blend of spices for its distinctive flavor. Fennel seeds are a key ingredient, adding a mildly peppery, fresh note that complements the richness of the meat. Garlic, black pepper, and coriander are also essential, providing depth and warmth. Optional additions like paprika or cayenne can add smokiness or heat. These seasonings enhance the savory profile without overpowering the natural taste of the meats. Balancing flavors ensures a harmonious and aromatic sausage that appeals to a variety of palates.

Casings and Binding Agents

Casings are essential for shaping and preserving the sausage’s structure. Natural casings, like animal intestines, provide authenticity and snap when cooked. Synthetic casings are durable and uniform, ideal for consistent results. Binding agents, such as eggs or breadcrumbs, help hold the meat mixture together, ensuring juiciness and texture. Proper preparation of casings, including rinsing and soaking, prevents tearing during stuffing. Binding agents also enhance moisture retention, making the sausage more flavorful and tender. Their role is crucial for achieving the desired texture and appearance in high mountain summer sausage.

Equipment Needed

A meat grinder, sausage stuffer, and smoker or oven are essential tools for making high mountain summer sausage, ensuring proper processing and cooking of the final product.

Meat Grinder

A meat grinder is a crucial tool for processing meats evenly, ensuring the right texture for summer sausage. It allows for consistent grinding of meats, preventing uneven particle sizes that can affect flavor and texture. Regular maintenance, like sharpening blades and keeping parts clean, is essential for optimal performance. Using a meat grinder helps mix meats and fats thoroughly, which is vital for creating a uniform blend. Proper grinding also ensures the sausage holds together well during stuffing and cooking, making it a foundational step in the process.

Sausage Stuffer

A sausage stuffer is essential for evenly filling casings with the meat blend. Manual or electric stuffers are available, with electric models offering faster processing for large batches. Proper lubrication and casing preparation are key to avoid tears. Stuffing should be done gently to prevent air pockets, ensuring uniform flavor distribution. Regular cleaning and maintenance of the stuffer are crucial for longevity and food safety. Using a sausage stuffer ensures the casings are filled consistently, which is vital for achieving the desired texture and appearance in high mountain summer sausage.

Smoker or Oven

A smoker or oven is crucial for cooking high mountain summer sausage, ensuring the development of its signature flavor and texture. Smokers provide a traditional, slow-cooking method with wood smoke, enhancing the sausage’s savory profile. Ovens offer a more controlled environment for even cooking. Both methods require precise temperature control, typically between 150°F and 200°F, to prevent overcooking. Monitoring the internal temperature is essential to achieve food safety and desired consistency. Proper cooking ensures the sausage is tender, flavorful, and ready for storage or immediate enjoyment.

Step-by-Step Instructions

High mountain summer sausage crafting involves precise steps: meat preparation, spice blending, stuffing casings, fermentation, and controlled cooking to ensure safety, flavor, and texture perfection.

Preparing the Meat and Spices

Start by selecting high-quality meats, trimming excess fat for balance. Grind the meat finely and mix with spices like fennel seeds, which add a peppery, fresh flavor. Ensure even distribution of seasonings. Refrigerate the mixture to prevent bacterial growth and enhance flavor development. This step is crucial for achieving the signature taste and texture of high mountain summer sausage. Proper preparation ensures a harmonious blend of flavors and a safe fermentation process.

Mixing the Meat and Spice Blend

Combine the ground meat with the spice blend, ensuring even distribution for consistent flavor. Use gloves to mix thoroughly, preventing compacting. Add any additional ingredients like fennel seeds gradually. Mix until just combined to avoid overworking the meat. Cover and refrigerate the mixture for at least 30 minutes to allow flavors to meld. This step ensures the sausage develops its signature taste and texture, preparing it for stuffing into casings. Proper mixing is vital for achieving a balanced and aromatic high mountain summer sausage.

Stuffing the Casings

Attach the casings to the sausage stuffer, ensuring no air pockets form. Gently fill the casings with the meat mixture, avoiding overstuffing. Use a consistent, steady pace to maintain even distribution. If air pockets appear, gently massage the casing to eliminate them. Once filled, twist the casings into desired links or leave as a continuous rope. Refrigerate the stuffed sausages for at least 30 minutes before fermentation or cooking. Proper stuffing ensures uniform flavor and texture in the final product, making it essential for high mountain summer sausage quality.

Fermentation Process

The fermentation process is crucial for developing the sausage’s signature tangy flavor. Place the stuffed casings in a controlled environment, such as a fermentation chamber, at 68-72°F (20-22°C) with 60-70% humidity. Allow the sausages to ferment for 2-4 days, monitoring pH levels to ensure they drop below 5.3 for safety. This step enhances flavor complexity and prevents spoilage. After fermentation, the sausages are ready for cooking or drying, ensuring a delicious and traditional high mountain summer sausage experience.

Cooking the Sausage

Cooking high mountain summer sausage requires careful temperature control to ensure safety and flavor. Smoke the sausages at 160-180°F (71-82°C) for 4-6 hours, or until the internal temperature reaches 160°F (71°C). Alternatively, bake in a preheated oven at 175°F (80°C) for 2-3 hours. Monitor closely to prevent overcooking. For traditional methods, air-dry at room temperature for 24 hours before cooking. Avoid high heat to prevent casings from cracking. The result is a tender, flavorful sausage with a dry, firm texture, perfect for snacking or charcuterie boards.

Storage and Shelf Life

Proper storage is crucial for maintaining the quality of high mountain summer sausage. Store it in a cool, dry place or refrigerate for up to 6 months. For longer shelf life, freeze at 0°F (-18°C) for up to a year. Ensure the sausage is tightly wrapped to prevent moisture exposure.

Proper Storage Techniques

Proper storage techniques are essential to maintain the quality and safety of high mountain summer sausage. Store it in an airtight container or wrap it tightly in plastic wrap or aluminum foil. Keep it in the refrigerator at a consistent temperature below 40°F (4°C) to prevent bacterial growth. For longer storage, place the sausage in a sealed bag or vacuum-sealed container and freeze at 0°F (-18°C). Avoid exposing the sausage to direct sunlight or moisture, as this can lead to spoilage or mold growth. Always check for signs of spoilage before consumption.

Refrigeration and Freezing

For short-term storage, refrigerate high mountain summer sausage at 40°F (4°C) or below. Wrap it tightly in plastic wrap or aluminum foil to prevent drying. For longer storage, freeze at 0°F (-18°C) in airtight containers or vacuum-sealed bags. Freezing preserves flavor and texture for up to 6 months. When thawing, place the sausage in the refrigerator overnight to maintain moisture. Avoid frequent freezing and thawing to prevent quality loss. Proper refrigeration and freezing ensure the sausage remains fresh and safe to eat for an extended period.

Serving Suggestions

High mountain summer sausage pairs perfectly with cheeses, crackers, and charcuterie boards. Its rich flavor makes it a versatile and appealing option for appetizers or snacks.

Pairing with Cheeses and Crackers

High mountain summer sausage is a perfect complement to a variety of cheeses and crackers. Try pairing it with sharp cheddar, gouda, or brie for a rich flavor contrast. Serve with sturdy crackers like water crackers or wheat thins to hold up to slicing. Add garnishes such as fresh grapes, figs, or a drizzle of honey for a sweet and savory combination. This pairing is ideal for quick snacks, picnics, or casual gatherings, offering a balanced and satisfying flavor experience.

Adding to Charcuterie Boards

High mountain summer sausage is a standout addition to any charcuterie board. Its robust, savory flavor pairs perfectly with cured meats, artisanal cheeses, and fresh garnishes. Slice the sausage thinly and arrange it alongside prosciutto, salami, and a variety of cheeses like cheddar or gouda. Add crackers, nuts, and fresh fruits such as grapes or berries for a well-rounded presentation. This combination creates a visually appealing and flavorful snack that’s ideal for entertaining guests or enjoying as a quick, satisfying meal.

Health Considerations

High mountain summer sausage is high in protein but may contain sodium and saturated fats. Moderation is key. Opt for lean meats and spices like fennel for added flavor without extra salt, supporting a balanced diet.

Nutritional Value

High mountain summer sausage is a nutrient-rich food, high in protein and iron, making it a satisfying option. It contains healthy fats, including omega-3 fatty acids, which support heart health. However, it is also high in sodium and saturated fats, so moderation is advised. The spices, like fennel and garlic, add antioxidants and flavor without extra calories. Pairing it with vegetables or whole grains balances the meal. For those concerned about fat content, leaner meat options can be used during preparation to reduce saturated fat levels while maintaining its hearty, savory appeal.

Preservation Methods

High mountain summer sausage can be preserved through smoking, curing, or fermentation. Smoking adds a rich flavor while extending shelf life. Curing with salt or sugar prevents bacterial growth. Fermentation creates lactic acid, enhancing flavor and preservation. Proper storage in airtight containers or vacuum-sealed packaging maintains freshness. For long-term storage, freezing is recommended. Always ensure the sausage is dried thoroughly before storing to prevent mold. These methods help retain the sausage’s quality and safety for future enjoyment. Regularly checking for signs of spoilage is crucial for maintaining its integrity.

Troubleshooting Common Issues

Common issues include mold growth and dryness. Ensure sausages are thoroughly dried before storage to prevent mold. Monitor humidity and temperature during fermentation to avoid dryness.

Dealing with Mold

Mold can develop if sausages are not properly dried or stored. Regularly inspect sausages for white or green spots. Discard any affected links to prevent spread. Ensure fermentation and storage areas maintain consistent, low humidity. If mold appears, wipe with vinegar solution and adjust environmental conditions. Proper air circulation and temperature control are crucial. Always use fresh, high-quality ingredients to minimize mold risk. Immediate action is essential to preserve sausage quality and safety.

Preventing Dryness

To prevent dryness in high mountain summer sausage, ensure consistent humidity during fermentation and storage. Use natural casings to retain moisture and promote even drying. Avoid overcooking, as high heat can dry out the sausage. Store sausages in airtight containers or vacuum-sealed bags to maintain humidity. Keep them in a cool, stable environment, ideally between 32°F and 40°F. Regularly monitor sausages for dry spots and adjust storage conditions if necessary. Proper handling and storage techniques are key to preserving juiciness and flavor.

Additional Tips and Variations

Experiment with spices like garlic or herbs to create unique flavor profiles. Swap traditional meats with alternatives for a modern twist, enhancing the sausage’s versatility and taste appeal.

Using Different Spices

Experimenting with various spices can elevate your High Mountain Summer Sausage. Fennel seeds add a mildly peppery, fresh flavor that complements the meat’s richness. Smoked paprika introduces a smoky depth, while garlic powder provides an aromatic twist. Cayenne pepper can add subtle heat, and black pepper enhances the seasoning. Each spice offers a unique dimension, allowing you to customize the flavor. Balancing these elements ensures a harmonious taste, making each batch distinctive and satisfying. This approach keeps your sausage-making versatile and exciting, always yielding a delicious outcome.

Alternative Cooking Methods

High Mountain Summer Sausage can be cooked using various methods beyond traditional smoking. Grilling adds a smoky char, while pan-frying achieves a crispy exterior. Air frying offers a healthier option with less oil, maintaining juicy texture. Sous vide ensures even cooking and precise temperature control. Each method enhances the sausage’s flavor uniquely, allowing for versatility. Whether grilled, pan-fried, or air-fried, the result is a delicious, savory sausage tailored to your preference. These alternatives make it easy to enjoy High Mountain Summer Sausage in diverse ways, always delivering a satisfying meal.

Origin and Cultural Significance

High Mountain Summer Sausage traces its roots to European traditions, where sausages were staple foods. Its cultural significance lies in its hearty, flavorful profile, enriched by spices like fennel seeds, reflecting a rich culinary heritage.

European Roots

High Mountain Summer Sausage draws inspiration from European sausage-making traditions, particularly from Germany and Italy. These cultures perfected the art of blending meats with spices like fennel seeds, creating robust flavors. The use of fennel seeds, a common European practice, adds a fresh, mildly peppery taste that balances the richness of the meat. This heritage has influenced the creation of High Mountain Summer Sausage, blending traditional techniques with modern adaptations to preserve its cultural and culinary significance.

Modern Adaptations

Modern recipes for High Mountain Summer Sausage incorporate contemporary twists while respecting traditional methods. Chefs often experiment with diverse meats and spices, such as fennel seeds, to enhance flavor profiles. Swapping ingredients like cavolo nero for spinach or lentils offers versatility. These adaptations cater to modern tastes and dietary preferences, ensuring the sausage remains relevant. While the core techniques stay true to their European roots, innovative approaches like alternative cooking methods or ingredient substitutions keep the dish fresh and exciting for today’s culinary enthusiasts.